Our company takes a leading position in the construction wooden houses for many years. One of the directions is the construction of baths from chopped logs, with an area of 9 m². You have the opportunity to build a wooden bathhouse on your site for a low cost; you can choose from already ready-made options, or order an individual design based on personal preferences. Such baths combine the characteristics of the construction of ancient baths and have remained popular for more than a hundred years. This is due to the availability of materials used in construction.

The quality of processing of materials and assembly of the bath ensures heat retention, reducing the risk of mold development or insect damage, which ensures a long service life.

Chopped baths have won a special reverent love among the inhabitants of our country many centuries ago. The urban rhythm of life has only increased the desire of people to retire and relax their souls in a bathhouse made of chopped logs. At the same time, such buildings also carry folk memory, as well as Russian traditions. It is no coincidence that we can see precisely chopped colorful baths next to modern elite buildings.

The construction of a bathhouse begins with the preparation of logs; there are several ways to do this. The first method involves removing only the bark from the tree trunk, and is called debarking. Such logs are distinguished by their slightly rough appearance. The second method involves stripping with a scraper, a special tool for wood. The tree acquires aesthetic beauty. The third method is to process the trunk with a plane, visually resembling a rounded log appears, but at the same time all the technical parameters of the material are preserved.

For all your questions and calculation of the cost of the bath, you can contact our managers. They will provide you with complete information and help you choose the optimal materials for construction. Already ready-made solutions presented on our website, if none of them suits you, we will definitely help you decide and create your project. We guarantee the durability of the baths we build and guarantee the quality and environmental friendliness of the materials.

Log baths have always been a special part of the life of the Russian people. They were regarded not just as hygiene products, but as a source of strength and youth. Another famous historian N.N. Kostomarov wrote that at the slightest sign of illness, a Russian goes to the bathhouse to take a steam bath, and the first mentions of these simple structures and traditions date back to “The Tale of Bygone Years.” In addition, the log sauna is invariably part of the Russian family tradition, and to this day many people gather with the whole family on weekends or meet with close friends in the log sauna, in a warm, kind and frank atmosphere. But is a log sauna as simple as it seems at first glance? Let's try to figure it out.

Advantages of log bathhouses

First of all, it is necessary to evaluate the merits of bathhouse projects made from logs, namely from natural materials processed by hand. Today, saunas are widespread, but they cannot be compared with traditional steam rooms. Firstly, there is no such healing effect, because modern electric saunas can be installed in almost any room. The basis of such a sauna may end up being exclusively artificial materials, which are often poorly ventilated, unlike log sauna projects, and when the temperature rises they can even release carcinogenic substances. Therefore, let’s discard fashionable Western parodies and look at time-tested traditions.

- It is obvious that a log bathhouse is an environmentally friendly building. Instead of harmful chemical compounds, when heated, phytoncides are released into the air;

- Any type of wood gives an amazing natural aroma when heated. A essential oils Such miraculous species, such as cedar, are even considered healing. It must be emphasized that this is not speculation, but a real fact, because the Egyptians even used cedar in medicine and for embalming;

- the aesthetics and originality of a log bathhouse is generally a topic for a separate discussion. The shape of the hand-chopped material allows you to create unique works of construction art that will improve the area of any home;

- projects of log baths are so diverse that even the most fastidious esthete will be able to find something of his own from our proposals. Or even design the bathhouse of your dreams from scratch;

- the construction of baths turns out to be of much higher quality than alternatives. Hand-cut logs do not crack much, serve and retain their original appearance much longer.

Construction of baths from logs: choice of wood

The construction of a log bathhouse should be approached with no less attention than that of houses. After all, each material has its own specific characteristics. Let's get acquainted with the most common ones.

First of all, you should pay attention to hardwood. And let's start with aspen, since this breed became the ancestor of Russian baths. This is easily explained, because previously peasants could not afford coniferous forest - it was protected, and aspen, which grew everywhere, was not in short supply. In addition to these properties, the material has an acceptable cost, which explains its popularity.

Bathhouse projects made from linden logs will be slightly more expensive than those made from aspen. This is explained by the remarkable properties that have been used since ancient times in all spheres of peasant life. The special atmosphere and strength of this wood species makes it an excellent basis for construction. Bathhouses made of logs, the prices of this species are due to the low percentage of logs being harvested, since linden is not so widespread.

The leader of the deciduous forest in terms of quality is oak. It is also not widespread, but has excellent strength characteristics and beauty. However, you need to take into account that it is very dense and heavy, so when building bathhouses from logs it is used mainly for the lower crowns. In terms of cost, oak is superior to previous species; accordingly, the price of a bathhouse made from oak logs will be much more expensive.

If we talk about coniferous species, then pine has a leading position. This is primarily due to its widespread distribution and reasonable cost. Phytoncides, resin aromas and pleasant appearance make this coniferous species one of the most popular for the construction of log baths.

Spruce is similar in quality and price. This wood creates a unique aroma in the log bathhouse, and retains its original appearance for a long time. In many qualities it is on par with the previous material.

More expensive species include fir, cedar and larch. The last two breeds demonstrate the best performance both in terms of aromas and healing properties, and strength. In terms of durability, a bathhouse made of larch is clearly the leader. This material is not subject to rotting, exhibits minimal shrinkage and cracking, this rock is very hard, and after being in water it becomes even stronger. Due to heavy processing, larch is rarely used for the construction of an entire turnkey log bath; it is usually used for the lower crowns. In addition, the prices of a log bathhouse built entirely from larch will be too high.

Log bathhouse projects: architectural features

In terms of architecture, there are practically no restrictions when building log baths. Everything depends only on the imagination and preferences of the customer. However, it must be taken into account that some architectural features not worth missing out on.

The use of chopped logs in the process of building a bathhouse is fully justified by the high costs. Since the quality of such a structure is much higher than the use of rounded materials. Let's look at how to build a bathhouse from a log below.

Chopped log: features and advantages

The most popular material used in the construction of a bathhouse is wood. Exactly wooden buildings They are distinguished by quality, durability, and spending time in such a bathhouse becomes beneficial to health.

The use of wood allows you to maintain the necessary microclimate of the room; the walls in such a bathhouse are capable of absorbing moisture under certain conditions and releasing it at the right time.

The duration of use and the quality of the constructed bathhouse directly depend on the type of materials used in the process of its construction and their quality. When harvesting wood, you should adhere to certain rules, which we will consider below:

1. It is better to harvest wood from December to March.

2. After the tree is cut down, you should wait at least a month before further processing.

3. Before storing the timber, all logs are cleared of bark, only small areas of 15-20 cm with bark remain at the end sections, preventing them from cracking.

4. Logs are stored in stacks. It is important to maintain a ventilation gap between them of 50 mm.

5. All stacks are covered with slate, which will protect them from moisture.

If you adhere to all the conditions for harvesting wood, then such a bathhouse will serve its owners for at least 50 years.

Logs are round materials that are formed after cutting down trees, which are cleared of branches and trunks.

Among the advantages of chopped logs are:

- less creaking and cracking;

- lower level of moisture absorption;

- higher resistance to biological influences in the form of insects, fungus or mold;

- Duration of operation that does not require special care;

- ease and simplicity of assembly;

- the presence of special groove components;

- a variety of corner notches in the form of a paw, Russian bowl, exclusive triple notch;

- a variety of styles for performing a bath;

- healthy indoor microclimate;

- wide range of log diameters.

Among the disadvantages of chopped logs are:

- higher cost of work on preparing the material;

- difference in diameters at different ends of the frame;

- the quality of the work directly depends on the experience of the specialists who perform it; if the installation is performed poorly, the appearance of the structure suffers greatly.

Saunas made of chopped logs - characteristics

Saunas made from chopped logs have remained popular for decades and even hundreds of years. This is due to the availability of materials used in the process of their construction and the ease of processing.

Using wood in construction has the following advantages:

- first of all, the ability of wooden walls to “breathe” - thanks to this, it is easy to breathe in the bathhouse, and there is fresh air and a healthy atmosphere in the room;

- low level of thermal conductivity ensures excellent heat retention in the bath, even in winter time, which is very important for taking bath procedures;

- making walls in a bathhouse from wood allows you to avoid overheating in the summer, since wood controls the temperature level in the room;

- cost is another advantage, since a wooden bathhouse does not require the construction of an expensive foundation, and wood is much cheaper than brick or concrete.

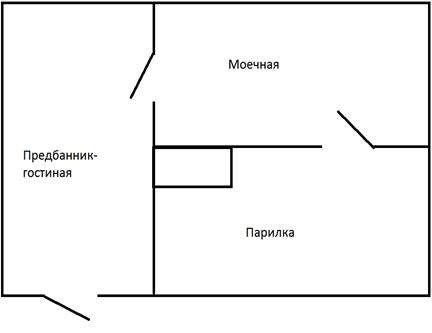

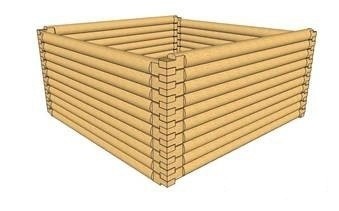

The standard appearance of the bathhouse, built from chopped logs, has one floor. Although it is possible to build a two-story or attic bathhouse. The minimum number of rooms in a bathhouse is three: a washing room, a steam room and a relaxation room.

In the construction of baths they use different breeds trees, but the lower part of the bathhouse, which is in contact with the foundation, is traditionally made of larch, since this material has the highest quality characteristics. In addition, it is common to use coniferous trees, pine, spruce, which fill the room with a special aroma that cleanses and heals the human body.

For the firebox it is better to give preference to birch. When building a bathhouse, the main thing is to choose the right type of wood. Since the final result of the work depends on the quality of the material.

An important point is the construction of load-bearing structures of the building. They appear as one wooden wall, which is based on longitudinally laid logs or crowns.

Chopped log baths photo:

The crown is a rectangular structure, which consists of beams laid in a perpendicular direction.

The final stage of work is cutting down the bathhouse; first, work is done on cutting down a tree in the forest or in the field. Next, the log house is transported to the construction site and caulked. After a year after installation and complete drying, internal and exterior decoration log house

Construction of bathhouses from logs: step-by-step instructions

The procedure for constructing a bathhouse using chopped logs consists of several stages, namely:

1. Drawing up projects for bathhouses made of chopped logs.

2. Assembly and felling of materials used in the construction process.

3. Preparation and construction of the foundation.

4. Construction of walls in the bathhouse.

5. Equipment for the roof of the building.

6. Installation of the stove.

7. Carrying out interior finishing work.

8. Installation of the chimney.

9. Work on insulation of floors and ceilings.

10. Installation of shelves indoors.

The first stage involves carrying out work on designing a bathhouse. Project development is carried out in accordance with all the requirements of the owners. Possible option self-development project, ready purchase of the project or individual development of the project by specialists who will take into account all the individual climatic and geological features of the area and draw up best option bathhouse project.

They begin to build a bathhouse by determining its dimensions, if we consider standard sizes log house, which consists of three rooms, its area will be about 60 square meters.

An important factor is the height of the room in which the shelves will be located, and which should be comfortable for a certain number of people.

Please note that too large a bathhouse will improve heat loss and you will need to spend a lot of fuel to heat the bathhouse. Therefore, you should choose the minimum dimensions of the room, which should be convenient for the location of people in the bathhouse.

A standard bathhouse consists of a dressing room in which people change clothes, and a steam room in which they wash and steam. It is possible to equip a rest room.

For a more rational use of space, the door from the steam room should open into the vestibule.

To improve the strength of the structure, you should select and arrange the foundation correctly. The depth of its laying is determined by the depth of soil freezing, to which a minimum of 100 mm is added.

It is important to take into account the correct temperature distribution in the bath. The air temperature in the steam room is from 51 to 57 degrees, in the washing room - 35-40 degrees, and in the locker room, at least 22 degrees.

An important factor is correct location and installation of shelves. They should not be near the stove, as there is a risk of burns from too hot steam.

Therefore, it is preferable to place shelves near blank walls. The shelves should be arranged in two or three tiers, depending on the height of the ceiling.

Most often, heaters are used in the bathhouse, which are located in the corner of the room. This arrangement allows for optimal heating of all rooms at once. A reservoir is installed in the inside of the furnace in which water is heated. The principle of operation of such a furnace is to use a special kind of stones, which, when heated, become heated and release steam in contact with water. Firewood is used as fuel for the heater stove, which is used to heat it for a long time.

The arrangement of the roof is another important issue, since the roof must have minimal thermal conductivity. If the bathhouse is a separate building, then the most popular option for constructing a roof is gable roof. When arranging bathhouses in the form of an extension, it is rational to use single-pitch roofing types.

The angle of inclination of a gable roof is from 18 to 44 degrees, and that of a single-pitch roof is from twenty to thirty degrees. Wooden sauna requires a heavy roof, as it must be very warm to prevent heat loss. Quite popular are Norwegian earthen roofs, on the surface of which there is soil and plants in the form of a lawn.

It will take at least two months to build the bathhouse. But, keep in mind that in order for the bathhouse to serve well, its operation should begin no earlier than a year after its construction. Since it is after this period of time that the first stage of shrinkage of the bath occurs. Final shrinkage will occur after four to five years, depending on the type of tree.

The main stage in the construction of a bathhouse is the insulation of the floor and ceiling. To insulate the ceiling in a bathhouse from chopped logs, you will need to nail slings all over the ceiling, then install a wooden ceiling, then install caulk to prevent heat loss.

In addition, care should be taken to properly arrange the floors and drainage. When constructing a floor in a room for washing and steam rooms, you should take care to ensure normal drainage and drainage of water into sewer system. Therefore, the floor must have an inclined surface; for its manufacture, exclusively moisture-repellent materials are used, in the form of concrete and clay.

The slope should be directed towards the pit, which is equipped with a water seal connecting the drainage pipe and the sewer pit.

Next is the floor covering. wooden materials. To carry out this process, it is necessary to install logs, which are mounted on a pre-waterproofed surface with support pillars. A gap of at least 0.5 cm must be left between the boards, since wood swells when wet and decreases in volume when dry. In addition, you should take care to remove the longitudinal chamfer from the boards, so their upper part becomes a little larger than the lower part.

If a solid floor is being constructed, then its arrangement requires the presence of a pit directly in the room. A special grille is installed to cover it. The ventilation riser is used for sewerage equipment. To equip it, it is necessary to install asbestos-cement or metal pipe, the minimum diameter of which is 10 cm. A cap or deflector is installed on its upper section.

Technology for building a bathhouse from chopped logs

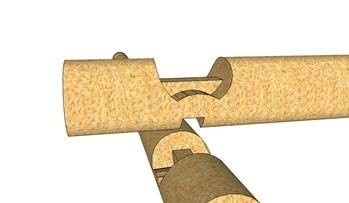

After the construction of the bathhouse, it is necessary to lay an inter-crown seal between the logs. This eliminates the appearance of cracks through which heat loss occurs.

Moss or tow is used as a sealant, but this method is less popular due to the complexity of the work and the high cost of the material. Modern house construction involves the use of flax wool, which is easy to install, as it is produced in the form of a roll.

The procedure for sealing seams is called caulking; it requires the same inter-crown sealant or linen rope - which improves the appearance of the building.

With the help of caulking, the thermal insulation of the entire building is significantly improved. But this process should be repeated after the building has settled, that is, after five years of its operation.

An important issue is the problem of joining logs, since chopped materials have unequal diameters and joining requires special skills.

The standard size of a log is 600 cm. If the wall of the building is longer, then they are joined together at the point of cutting. Thus, the joint areas become invisible. In the absence of a perpendicular wall, a cut is installed at the joint section to hide the joints.

If it is not possible to construct a cut, the joints are formed in a checkerboard pattern for more reliable fixation of the logs.

Making a bathhouse from wood has another unpleasant consequence, such as cracking of the log. Since wood is a living organism with moisture inside it, after certain processing it dries out and loses its strength. Since moisture begins to evaporate from the central part of the logs, the heaviest load is placed on them, leading to cracking. To avoid this process, it is necessary to make a deformation cut, which will help remove moisture without consequences for the log.

In addition, there is a danger of the wood turning blue or darkening. This procedure occurs due to a decrease in the quality of wood under the influence of moisture, sun, temperature changes and other factors. Logs are especially sensitive to fungi or mold that are in the air and through it reach the surface. The most optimal conditions For fungus to multiply, the air temperature is +22 and the humidity is more than 90%, so it is recommended to equip the bathhouse with good ventilation, which will prevent this process.

In addition, it is necessary to periodically treat the wood with antiseptic preparations and impregnations. If blue stains have already appeared on the surface, then it should be sanded well and a bleaching agent should be applied.

Before installing the beams, you should take care of their treatment with the help of preparations that will protect the wood from the sun, moisture and other external influences. You should not save on purchasing these materials, as they can extend their service life. wooden bath several times.

Log sauna video:

Is there anything in this world comparable to the pleasure that comes from spending a few hours with family and friends in your own steam room? A real chopped bathhouse built with my own hands, is the pride of any owner. In this article we will briefly tell you about the basics of building a log bathhouse with your own hands at all its stages: foundation, choice of wood, lower crown, walls, roof, floor and several typical layout options.

Foundation for a chopped bathhouse

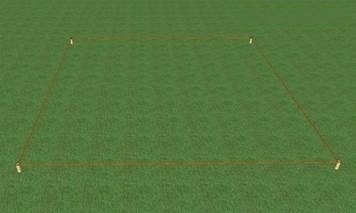

Construction work begins with studying the site, carrying out all the necessary calculations and designing a bathhouse. In our case, given that this will be a log house, a simple preliminary design, in which the main parameters of the future building will be entered. As soon as the size and shape of the structure are indicated, the exact location for the bathhouse on the site is determined, you can begin to build the foundation.

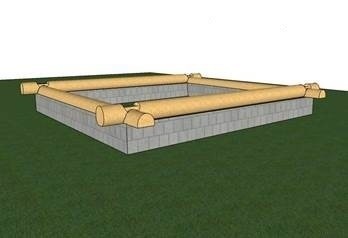

Appearance strip foundation everyone knows - these are concrete strips on which they rest load-bearing walls. The base of the strip foundation should be 10 cm wider than the wall - this will be more reliable and stable.

First you need to mark the area:

Clear the area of debris, mark the place where the first corner of the building will be located, drive a peg and mark it with a triangle or any other way. On one side of the mark, measure the length that, according to our calculations, the longitudinal wall of the structure has. On the other side, measure a distance equal to the transverse wall in the center lines. Having determined the points where the walls will end, drive in the second and third pegs. Calculate the place opposite the first corner of the bathhouse, drive another peg there and move the triangle. Ideally, the result should be a rectangle, the difference between the diagonals of which does not exceed 2 cm.

After marking, we begin digging a trench. If the soil on your site is sandy, then it is enough to dig a ditch 50-60 cm deep, if the soil is clay, you can deepen the ditch. After you have dug a trench, you need to surround it with an edged board, strengthening the edges - this will be formwork. As a rule, for such work, edged boards with a section of 150 by 25 mm are used. When installing, please note: the height of the formwork must exceed the height of the foundation by 10-15 cm. When wet or clay soil It’s better to prepare a good sand cushion.

Edged boards are the best option for formwork: this material has a flat surface, which can significantly reduce the cost of subsequent front finishing of the finished foundation.

Wood selection

Properly selected wood is half the success. As a rule, log baths are built from deciduous and coniferous trees, distinctive feature which are strength and moisture resistance. It can be larch, pine, spruce or oak. For the construction of a bathhouse, it is recommended to choose well-dried logs with a diameter of 200x250 mm. Wood moisture content should be within 10%. More 100% sauna timber to choose from

The basis of a chopped bath: we install the lower crown

The lower crown stands on the foundation, in close proximity to the ground and gets wet more than other crowns during precipitation. Before laying the first, lower crown, it is necessary to waterproof the foundation to prevent the walls in the lower part of the building from getting wet. To do this, it is enough to lay 2 or 3 layers of bitumen waterproofing material between the foundation and the logs.

The lower crown, which is called the frame, is made from thick logs. For greater reliability and durability of the structure, the frame is often made from a species that is highly resistant to rot and moisture - larch or oak.

The first crown can be laid in one of the two ways described below.

- First way. Two logs are placed on the foundation parallel to each other, having previously cut off 4-5 cm from each for a tight fit. Insulation is laid between the log and the waterproofing - it can be tow, jute or moss. Two more logs are also laid parallel to each other on the two free sides, strengthening them on the first hewn logs.

Advantage: the logs undergo minimal processing and remain intact, if you do not take into account the removal of 4-5 cm, which makes the flashing durable and strong.

Disadvantage: the appearance of too large gaps between the foundation and the logs, which must be sealed with bars, bricks or log particles. Alternatively, you can pour a foundation with different levels of perpendicular sides.

- Second way. Four logs are selected for the crown. Two of them are cut off by half, the remaining two - by 4-5 cm. With this installation, there are no gaps between the crown and the foundation. At the joints, the logs are joined using the corner joint method.

Advantage: no gaps and tight fit to the foundation.

Disadvantage: part of the log is removed, which violates its integrity and makes the wood less durable.

Important: To reduce the risk of rotting of the lower crown, it is advisable to treat that part of the hewn logs that come into contact with waterproofing materials with an antiseptic before laying.

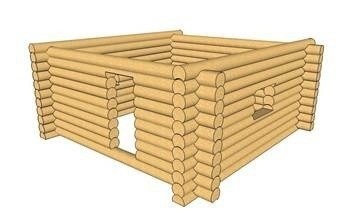

Walling

As soon as the lower crown is ready, you can start building the walls - you need to lay the logs horizontally, forming the crowns. At this stage you should Special attention pay attention to the corner connection of the walls, on which the solidity of the entire building depends.

Types of corner joints of logs

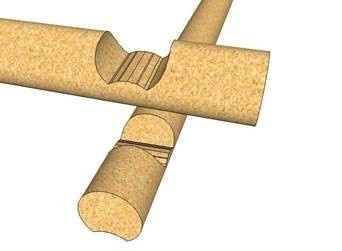

There are two ways to connect logs - a corner with a remainder and a corner without a remainder.

Angle with remainder - logs are connected in such a way that when connected they protrude beyond the walls of the structure by 20-30 cm.

Advantage: easy to manufacture, does not require additional insulation and is practically not blown through.

Disadvantage: material consumption is 10% more than with the “corner without residue” method.

Angle without rest: logs are connected to each other with wooden locks cut at the ends. In this case, the remains of the logs do not protrude beyond the walls of the building.

Advantage: aesthetics.

Disadvantage: high labor costs and the need to additionally insulate the walls from the outside. In addition, if the logs are not held together with dowels when joining “without any residue,” the log house will be less stable.

There are many types of corner joints with a remainder, but the two most common methods are:

Angle angle: in our case, this type of notch was used when laying the lower crown. In the upper and lower logs, recesses of the same size are selected, into which the logs then go. This method is rarely used nowadays, because it is too difficult and time-consuming to adjust the size of the recesses and make the joints airtight. As a rule, logs are connected “in a circle” if it is necessary for all the tops of the crown to be located in the same plane.

“Bowl” angle: a simple and practical method used in the construction of walls, which even an amateur can master. The top log fits into a recess in the bottom log, cut into a bowl that replicates the seat of the incoming log.

The most suitable option for a bathhouse is considered to be cutting into a bowl “in the tail”: a protrusion is left at the base of the bowl along the lower log, and a recess is selected in the upper log that is suitable in size to the protrusion.

Formation of walls

Having chosen one of the corner connection methods, you can begin to form the walls of the bathhouse, horizontally laying the crowns in the desired sequence. The grooves formed during installation between the crowns are filled with insulation. Traditionally, tow or moss is used for these purposes.

During the assembly process, you need to mark out places for windows and doors in the walls. Crowns can be made from individual pieces of logs or simply sawed logs in the designated places. It is advisable to do this right away, because if you cut out the windows later, the logs may become stuck, the partitions will drop and large gaps will appear between the covering log and the upper level of the partitions. When the frame is installed, you need to cut openings for the door and windows in the designated places using a chainsaw.

Important: windows and doors must be floating so as not to interfere with the natural changes in the dimensions of the log house during shrinkage. To do this, spikes are formed in the lower and side parts of the opening, 6-8 cm wide and 4-5 cm high. Windows and doors are installed in door and window frames.

Roof for a bath

The optimal solution for a chopped bath is gable roof, which, although it will cost more than a lean-to, will look more neat. Under the roof you can arrange a room for storing bath accessories and drying brooms.

The figure shows that the greater the angle of inclination of the slope, the less load it is subjected to during snowfalls.

As roofing material You can choose roofing felt, slate, ondulin, corrugated sheets, metal tiles. Any material within the financial capabilities of the bathhouse owner will do. The angle of inclination is selected depending on the selected roofing material.

Floor in a chopped bath

Wide choose modern materials allows you to make the floor not from wood, but from more durable and moisture-resistant materials. The wooden floor quickly gets wet and dries slowly, as a result of which the process of rotting begins, and unpleasant odors and microbes, which is harmful to health.

The best option for a bathhouse is a concrete floor covered with tiles.

Please note that the floor is made only after the installation of the sewer system.

Layout of a chopped bath

At the design stage, it is necessary to designate which rooms will be in the bathhouse and how to rationally distribute the total area between them.

As a rule, a bathhouse includes several rooms:

Tambour, optimal area 1 m2: the main function of the vestibule is to prevent moist or frosty street air from entering inside, otherwise front door condensation will freeze and it will be impossible to open it;

Locker room or rest room: according to the recommendations, the standard locker room area is determined at the rate of 2-4 m2 per person, if built small sauna for 4-6 people, it is enough to allocate 8-10 m2 for this room;

Washing room: according to the standards, 2.7 m2 per person is allocated for this room, some owners combine a washing room and a steam room;

Video on building a bathhouse with your own hands

And finally, a useful video:

We also recommend you:

“Treat yourself with a park and a broom!”, calls for a Russian proverb. What could it be better than a bath on a day off to cleanse your body and relax your soul? It is not surprising that, remembering the primordial Russian traditions, the owners country houses And country cottages More and more people are ordering turnkey log baths.

What are the advantages of chopped baths?

There are many companies on the market offering to create a building according to the most various projects and from the most different materials. Our offer for you is hand-cut logs. Why, what are its advantages?

Material

Hand-cut logs preserve the unique structure of the tree. It is not so susceptible to deformation, drying out, and premature cracks, since the protective layer under the bark is preserved. This building material is distinguished by a number of positive qualities:

- increased strength and thermal insulation properties, which is necessary for a bath. Since these are logs from the winter forest, they are especially dense and durable;

- good resistance to mold and insects even without treatment, although you still need to use an antiseptic;

- interesting and at the same time natural appearance: the log is not cylindered, therefore it retains its natural pattern and texture, only “smoothed” with a plane for smoothness;

- long service life. If treated with care, both children and grandchildren will use the bathhouse;

- What’s also especially good for setting up a bathhouse is that the winter forest tolerates it very well high humidity and temperature changes, it will serve faithfully without any problems.

Buy chopped sauna

A few tips when buying a log cabin.

- To ensure that your log house is truly made from winter wood, order it better in autumn, and build somewhere in February. Then in the summer it will be possible to begin interior decoration.

- Try to order the entire set of lumber from one reliable supplier, and do not waste time.

- The manufacturer must be direct. For example, our materials are from the manufacturer, and the prices are appropriate.

- Check the quality of building materials before starting to assemble the log house. However, our specialists will do all this themselves, and you won’t have to bother.

- Calculate in advance where the bathhouse will be located, where the windows and doors will open, whether the log house will interfere with free passage in the yard, whether it will be convenient to walk from the house to the bathhouse - this question is especially relevant in winter.

- Order turnkey construction - this way we will take care of the hassle from building the foundation to laying the roof, and you will simply enjoy the steam room.

The RuSrub company promises: such an important thing as a chopped bathhouse can be bought here relatively inexpensively from very high-quality wood from the northern Vologda forest. We take care of all our customers, building as we would build for ourselves.