These days I use a hair dryer for almost everything. Like any other type of household appliance, a hair dryer can also break. In order to repair a hair dryer with your own hands, you need to find out what it consists of. Almost any hair dryer consists of the following elements:

- Electric motor.

- Fan.

– Heating element.

– Electrical board.

It is the electrical circuit of the hair dryer that allows all the elements to work together. These are the main design elements. If the device is professional, then some elements may be added.

Hair dryers may be different, but hair dryer repair is no different in almost all cases. In that article we provided you with information that will help you repair this device. You will also learn how to repair a hair dryer with your own hands at home.

In order to repair a hair dryer, you will need to familiarize yourself with its design. To familiarize yourself with its design, you can disassemble the hair dryer. This process does not take much time. Usually its case is attached with screws, but sometimes the manufacturer may provide latches for attaching the case. That is why you need to be careful when disassembling, as sometimes inexperienced craftsmen can damage its body.

Each hair dryer has a motor that runs on direct current. The mains voltage is equalized using a diode bridge. If you purchased a cheap product, then in its design you can only find 1 diode.

As a rule, the switch in this device must simultaneously close the circuit through which the coils will be powered. It is these spirals that will start the motor in motion. Also, each device has a thermostat in its design. This device will monitor the temperature. If it starts to rise, then he will turn off the heater. If you have, then you can read how to repair it.

The procedure for inspecting and repairing a hair dryer

In order to repair a hair dryer, you need to inspect it. First of all, any inspection begins with the power circuit.

It is important to know! When performing all types of work that we described in this article, you must know the basic rules of working with electric current.

Below you can view detailed instructions, which will help you perform high-quality hair dryer repairs. This instruction is suitable for all types of hair dryers.

Cord

Before inspecting the cord, you must inspect the outlet. In most cases, it is this that causes the breakdown. If everything is fine with the outlet, then you can move on to inspecting the cord. You must perform all work only with the device de-energized. When inspecting it, you need to visually find the cause of the breakdown. If it is not there, then you should disassemble the hair dryer.

Inside this device, you may encounter several options for the electrical resistance of the wire:

- A pair of detachable contacts.

- Spike.

- The wiring is placed in plastic caps.

The last option is the most difficult when performing repairs. Repairing a hair dryer first begins with checking the wiring. The bell must be in two wires at the same time. When performing this type of inspection, you need to remember not to make more than two holes in the hair dryer wiring.

Almost everyone can inspect the contact pad of a hair dryer. You need to pick up this device and visually inspect it for damage. Usually if it has damage, then you can see it at first glance. Typically, the breakdown must be looked for at the junction with the hair dryer body. If so, then you should also check the cord.

Hair dryer switch and switch

When you are repairing a professional hair dryer, you need to close the switch and check how the hair dryer responds to this step. Before you start repairing your hair dryer, you need to write down the wiring diagram. The speed and temperature switch is checked using the same circuit.

If during inspection you find an element that is not working correctly, then you need to have it inspected. If you find carbon deposits, then you can remove it with an eraser. You need to wipe all contacts with alcohol. If you find broken parts, then you can replace them with analogues.

Fan

A clogged air duct is the most common hair dryer failure. To fix this problem, you need to remove the filter and clean it.

If the fan blades are not spinning, then you need to inspect the fan for hair. To clear it of hair you need to remove the propeller. At the same time, you need to avoid effort and distortion.

Spirals

Any hair dryer can have several heating elements. If you detect a break in the spirals, then you can fix this problem by twisting the wires. You can observe all defects in the heating elements visually. If the spiral cannot be repaired, then they need to be replaced with similar ones.

Chip

Sometimes the getinax backing may crack. That is why, in order to properly repair an electric hair dryer, you need to cover the damaged areas with solder. Sometimes damaged capacitors can swell. Typically, the top edge may contain cuts and when the product breaks, it may swell.

If this defect is detected, you will need to replace the capacitor. If you find resistors that burn out, then they need to be replaced.

Thermostat

Some hair dryers may have a self-regulating function. Typically this effect is achieved using a resistive divider. Further actions will depend on monitoring the parameter. But sometimes you can follow these recommendations:

- Remove the sensor completely and check the response of the device.

- Close the wires and see what happens next.

If there are no changes, then you need to download the circuit diagram of the hair dryer.

If you are planning to repair a professional hair dryer, then you may encounter problems. These devices may have additional elements, which include floating regulators and additional options. The spirals here are made of special alloys that emit negative ions when heated. When repairing a professional hair dryer, the repair technique remains the same:

- Inspect the cord;

- Switches and buttons;

- Clean the device from dust;

- Inspect the spirals;

- Check the motor;

- Visual inspection of capacitors.

Industrial models may differ from household hair dryers. Drying hair with industrial hair dryers is not recommended. Home repair of an industrial hair dryer may not end well.

Page 1 of 2

This electrical appliance - a hair dryer - is very popular and often indispensable in everyday life. Due to high consumer demand, the designs of most hair dryers have become very similar, and the quality of workmanship and price have dropped. Today, buying a truly durable hair dryer is very difficult. The practice of repairing hair dryers of various brands suggests that the breakdowns that occur are of the same type and, as a rule, are not fatal, but can be easily repaired without serious expenditure of money.

Any electric hair dryer in its design contains two main, large elements: a fan and a heater. The fan drives air through the heater (heating element), drawing it in behind the hair dryer and expelling it hot from the front.

Hair dryer device.

1 - propeller; 2 - electric motor; 3 - heater; 4 - thermal protection; 5 - mode switch; 6 - power cable.

For household hair dryers, the fan is built on the basis of low-voltage (12-18 V) DC commutator motors. Such a motor cannot be powered directly from a 220 V AC network. To achieve the required voltage drop, a separate coil (let's call it a step-down coil) is used inside the heating element. To rectify the voltage, a full-wave rectifier (diode bridge) is used, mounted on the contacts of the electric motor. A plastic propeller consisting of three or more blades is mounted on the metal shaft of the engine.

The heating element of the hair dryer is a frame made of fireproof material with several windings of nichrome wire (spiral). Depending on the number of operating modes of the hair dryer, there may be two or three windings, one of which is step-down.

Heating element with two windings.

Hot coils heating element must be constantly blown with cold air, especially when working on maximum power. If for any reason the air supply becomes insufficient or stops altogether (for example, the engine fails), then, for reasons fire safety and to avoid burning out the heating element, the hair dryer should turn off automatically. This emergency shutdown occurs due to the presence in the hair dryer of two heat-sensitive elements at once - two “lines of protection” inside the heater.

The first “frontier” is the thermostat. It consists of a pair of closed contacts attached to. Being close to the outlet of heated air, the contacts are intensively blown by it. When the exhaust air reaches a critical temperature, the contacts move away from each other, and the power supply circuit of the hair dryer opens. After a few minutes, when the bimetallic plate has cooled, the contacts will close again and the hair dryer will turn on.

Thermostats based on bimetallic plates.

If the above protection for some reason does not work at the right time, then a few seconds later the “second line” of protection is activated - the thermal fuse. This fuse is disposable and, after tripping, needs to be replaced.

Thermal fuse.

Rowenta CV 4030 hair dryer device.

To see the internal structure of a household hair dryer, let's look at its typical representative - Rowenta CV 4030. This model is equipped with a fan based on a low-voltage motor, the heating element consists of one reduction coil and two heating coils. The hair dryer has three operating modes; in the first operating mode, the fan speed is lower than in the other two. Schematic diagram This hair dryer is presented below.

In the first position of the switch SW1 mains power, passed through the fork XP1, filter C1R1, protective elements F1, F2, diode VD5(necessary to cut off one half-wave of alternating voltage) is supplied to the lowering spiral H1, the electric motor is powered through it M1. Diodes VD1-VD4 necessary for straightening the lowered spiral H1 alternating voltage. Inductors L1, L2 and capacitors C2, C3 serve to reduce interference that occurs during the operation of the brush motor. Via diode VD5 power is also supplied to the heating coil H2.

When you move the switch SW2 to position “2”, diode VD5 short-circuits and “goes out of the game.” The engine starts to operate at maximum speed, the spiral H2 heats up more. Third position of the switch slider SW2 corresponds to the maximum power consumption mode when parallel to the spiral H2 spiral is connected H3. In this position, the temperature of the exhaust air is highest. The “cool” button is included in the gap of both heating coils; when pressed, only the electric motor through the coil remains switched on H1, H2 And H3 are de-energized.

The process of opening the Rowenta cv4030 hair dryer.

Hairdryer in semi-assembled form.

Hairdryer without housing.

Bottom to top: switch SW1, capacitor C1 with a resistor soldered to it R1, button SB1, heating element, motor with propeller (in black casing).

A heating element.

Diode VD5(photo left) And The inductor coils (photo on the right of one coil) of the Rowenta CV 4030 hair dryer are mounted inside the heating element.

Thermostat (photo on the left).

Thermal fuse (photo on the right)

As a rule, hair dryers are quite often prone to various breakdowns, and you have to buy a new one. The device is not the most expensive, of course - you can easily buy another hair dryer, but at the same time it is quite simple, and many people will be able to restore its functionality without much effort.

Principle of operation

All hair dryers, regardless of the brand and type of case, have the same operating principle - an electric motor drives a fan, which drives air through heating coils. Hair dryers usually have a heat level switch, providing different thermal conditions, - the switch switches the serial connection of the required number of spirals, - the fewer of them there are in the circuit, the greater the current flowing - the greater the heating. Hair dryers are also equipped with thermal protection that turns off the device if it exceeds permissible temperature spirals. If such protection works, be sure to unplug the hair dryer from the network, because when the temperature drops, the thermostat will restore the electrical circuit and the hair dryer will work.

Basic faults

Troubleshooting involves disassembling the housing. It is usually held together with a pair of screws and latches on the body halves, which are quite easy to break, so you need to proceed carefully. Although there won’t be any special tragedy if the latch is broken - the case may well be held on by self-tapping screws, or during assembly you can apply spot glue in several places, but just a little - suddenly you will have to disassemble it.

The smell of burning– quite often encountered when using a hair dryer, since the fan sucks through the air intake not only air, but also hair, which then falls on the hot coil and, when burned, causes an unpleasant odor.

Another possible reason is insufficient air flow passing through the fan. This can be caused by blocking the ventilation grilles with your hand, or by clogging the filter, if one is provided in this model, with hair, fluff, dust, etc. A weak flow can also be caused by slow fan speeds.

Fan rotation slow– This is usually caused by hair wrapping around the motor shaft, which prevents it from rotating. As a rule, the fan is placed tightly on the shaft, and it is not possible to remove it for easy hair removal, since applying great force is risky - the fragile plastic can easily be broken. Therefore, it is convenient to use tweezers - gradually pinching off the wound hair with it until it is completely removed.

The opposite situation also occurs (much less frequently) - the fan does not sit tightly on the shaft, as a result the engine operates at normal speed, but the shaft rotates in the fan housing. The solution is simple - place the fan on the shaft using suitable glue.

The air comes out cold– in this case there may be several reasons:

- Poor contact in the mode switch - the solution depends on the design of the switch. Flexible elastic contact strips of an open type are often used - it is enough to bend them correctly or clean the contact points. If the switch closed type– replacing it is inexpensive.

- Broken wiring - the conductor leading to the spirals or switch may well break off or fall off at the soldering site.

- Broken heating coil. It won’t just break off - most likely it’s a burnout. It can be restored simply by twisting, but such a connection will not be durable - poor contact will gradually provoke carbon deposits, which will further increase the resistance at this point - as a result, sooner or later it will have to be repaired again. It is better to make the same twist, but then crimp it with a copper or brass tube of a suitable diameter (a thin tube from a refrigerator compressor works well). Soldering is useless in this case - the heating temperature of the spiral will melt the solder.

– there can be many reasons and almost all of them can be easily eliminated – a break in the power cord, lack of contact in the sliding contact pair at the point where the cord enters the housing, break in the internal wiring, lack of contact in the switch, etc. The worst that can happen is This is engine combustion. If you have something to replace it, that’s good (so don’t throw away old faulty hair dryers - they are spare parts after all), but if not, then you really need it new hair dryer– there is little chance of repairing the engine.

This household appliance has been helping to dry hair for more than 75 years - the first example of this electrical product appeared in the early 40s of the last century. Today there is a hairdryer in almost every home, and everyone knows the rules for its use. And here internal organization hairdryer is familiar only to some - we will try to fill this gap in knowledge.

Structural elements and operating principle

The design of the hair dryer is not complicated: the body is made of durable plastic, inside there is a miniature fan with a powerful electric motor and heating elements made of nichrome. optimal temperature, and then leaves the device through a tapering nozzle.

You can put it on the nozzle of a hair dryer to dry your hair. various attachments such as a comb or round brush for treating long hair, as is done on the product from Rowenta. Other attachments are also used - in the form of small and large combs different designs. A protective grille with a fine mesh is installed at the end of the device to prevent small objects and long hair from getting inside.

To regulate the speed of air passage, as well as the degree of its heating different models hair dryers have switches mounted on the pistol grip for user convenience.

The standard product designs are almost the same, with the exception of small nuances. The figure shows main parts of hair dryer:

- fan propeller;

- electric motor;

- heating element in the form of a spiral;

- base with thermal protection;

- start button and mode switch;

- power supply cord.

As can be seen from the diagram, the hair dryer is designed quite simply: the main components are heater and fan, which is built on the basis of a commutator type of miniature electric motors of 12-18 V. A plastic propeller is rigidly mounted on its shaft, the design of which varies depending on different manufacturers. The heating element is a base made of fireproof material, with wire threads or special spirals wound around its body. There can be several windings, which depends on the modes in which the hair dryer operates, but one of them must be step-down.

Hair dryer heater

Hair dryer fan

The photo shows a mini-motor and fan, and below is a heating element unit with two windings.

The coils must be constantly cooled by air flow so as not to overheat. If for some reason this does not happen, then the built-in overheating protection is immediately triggered - this is what distinguishes hair dryers from the most famous brands, for example, Philips or Rowenta.

Overheat protection system

The main purpose of a hair dryer is to dry and quickly style hair, while the temperature of the exhaust air sometimes reaches 60 degrees. Many devices are equipped with switches that regulate the speed of air flow and its heat. To protect internal parts from high temperatures, a protection system is installed that turns off the power supply to a working product in emergency cases.

Few users know where the name of a hair drying product like a hair dryer came from - sometimes a dry, hot, strong and rather gusty wind comes from the mountains to the valleys, which local residents gave the name föhn.

Any device modern model Two particularly sensitive elements are necessarily present:

Hair dryers are not as complex as they seem: a minimum of basic components, therefore, if available basic knowledge in electrical engineering, you can understand it if there is such a need. Full description can be found in the operating instructions for the specific product.

Typical faults

Let's consider the reasons for the failure of the main parts, because the failure of any of them guarantees the failure of the entire product, since it will not be possible to use it further without repair. You can carry out simple diagnostics yourself if you know the most typical problems of these household appliances.

If your home handyman is easily versed in electrical household appliances, then you will not need the services of professional craftsmen - all of the listed failures can be eliminated yourself.

Safe Operation

In order not to visit the service center frequently and save time and family budget, it is necessary to strictly comply with all operating requirements:

- Use only standard, factory-made extension cords.

- Inspect the cord before each use of the product and do not wrap it around the handle when storing.

- You can only use the supplied attachments that come with the kit.

- Do not use the product indoors with high humidity and do not allow water to come into contact with it.

- Install a special one in the air intake fine mesh filter, preventing hair from being sucked into the device.

- If any malfunction occurs, immediately disconnect the product from the electrical network.

- Do not pull the cord from the outlet or carry the device by the cord. Remember that the wires inside are not steel, but copper, which can be damaged by mechanical stress.

- Don't overheat the hairdryer, if you need a device for long-term use, purchase a professional device designed for long-term operation.

- Before storing the device, you must give it time to cool for at least half an hour.

- The product must be stored in a dry place, the drawer must be locked.

Recently, a hair dryer was brought to me for repair, not one of the most old-fashioned, but times are different now, who repairs a hair dryer for $10, and sometimes it’s easier to buy a new one, taking into account that the entire market is literally filled with cheap Chinese hair dryers. So, let’s take this opportunity to look at the design and operation of hair dryers.

The hairdryer operates on 220 V, 50 Hz. Any hair dryer has two main parts - a heating element and an electric motor.

A nichrome spiral is usually used as a heating element; it provides warm air. Hair dryers mainly use DC electric motors with a power of up to 50 watts, there are exceptions.

Passing through the spiral, the current loses its initial force, since the spiral has a certain resistance, it is this current that is rectified by the diode bridge and supplied to the electric motor.

Electric motors in hair dryers are designed for voltages of 12, 24 and 36 Volts; only very rare models use electric motors with a power supply of 220 Volts, in which case the voltage from the network is directly supplied to the electric motor. A screw (propeller) is attached to the engine rotor, which removes heat from the spiral, which is why the output produces a fairly strong directed flow warm air. The power of the hair dryer depends on the thickness of the coil used and the power of the installed electric motor.

The hair dryer that was brought was disassembled, it turned out that the problem was a broken track on the circuit board with the switches. After filling it with solder, the device worked fine.

But most often, the main reasons for malfunction are a broken spiral, a non-working motor, switch contacts melted from heat, a broken power cord or plug.

Elements in the diagram: 1 - diffuser nozzle, 2 - body, 3 - air duct, 4 - handle, 5 - cord anti-twist guard, 6 - "Cold air" mode button, 7 - air flow temperature switch, 8 - flow speed switch air, 9 - "Turbo" mode button - maximum flow air, 10 - loop for hanging a hair dryer.

The electric motor is supplied with DC voltage obtained through a diode bridge consisting of four diodes (or simply from one diode).

Let's highlight two elements of the circuit that are consumers (loads), these are the spiral and the diode bridge (we do not count the motor, because it is the load of the bridge). In the circuit, the elements are arranged in series (one after the other), which means that the voltage drop across each of them will depend on its own resistance and their sum will be equal to the network voltage in the third position of the switch.

Most entry-level hair dryers have a simple electrical circuit; such hair dryers have only one switch that turns on the fan and heating element. Heaters can be made in various modifications, but in all hair dryers they are made of nichrome twisted into a spring.

However, almost all simple modern hair dryers have 2-3 stages of power and air flow adjustment.

More advanced hair dryers have smooth controls for blowing speed and temperature of the blown air.

The recommended maximum operating time is 5 minutes. Upon completion of work, turn the temperature regulator to minimum, leave it on cold air for half a minute, and only then turn off the hair dryer. Try not to handle it with wet hands, otherwise moisture may get on the internal elements of the circuit, which can lead to a short circuit.

This household appliance has been helping to dry hair for more than 75 years - the first example of this electrical product appeared in the early 40s of the last century. Today there is a hairdryer in almost every home, and everyone knows the rules for its use. But the internal structure of a hair dryer is familiar only to some - we will try to fill this gap in knowledge.

The design of the hair dryer is not complicated: the body is made of durable plastic, inside there is a miniature fan with a powerful electric motor and heating elements made of nichrome.

You can put it on the nozzle of a hair dryer to dry your hair. various attachments The principle of operation is also simple: from the back of the product, as a result of the operation of the fan, an air flow enters, which is heated to the optimal temperature, and then leaves the device through a tapering nozzle.

such as a comb or round brush for treating long hair, as is done on the product from Rowenta. Other attachments are also used - in the form of small and large combs of different designs. A protective grille with a fine mesh is installed at the end of the device to prevent small objects and long hair from getting inside.

The standard product designs are almost the same, with the exception of small nuances. The figure shows main parts of hair dryer:

- fan propeller;

- electric motor;

- heating element in the form of a spiral;

- base with thermal protection;

- start button and mode switch;

- power supply cord.

As can be seen from the diagram, the hair dryer is designed quite simply: the main components are heater and fan, which is built on the basis of a commutator-type miniature electric motor of 12-18 V. A plastic propeller is rigidly mounted on its shaft, the design of which varies among different manufacturers. The heating element is a base made of fireproof material, with wire threads or special spirals wound around its body. There can be several windings, which depends on the modes in which the hair dryer operates, but one of them must be step-down.

Hair dryer heater

Hair dryer fan

The photo shows a mini-motor and fan, and below is a heating element unit with two windings.

The coils must be constantly cooled by air flow so as not to overheat. If for some reason this does not happen, then the built-in overheating protection is immediately triggered - this is what distinguishes hair dryers from the most famous brands, for example, Philips or Rowenta.

Overheat protection system

The main purpose of a hair dryer is to dry and quickly style hair, while the temperature of the exhaust air sometimes reaches 60 degrees. Many devices are equipped with switches that regulate the speed of air flow and its heat. To protect internal parts from high temperatures A protection system has been installed that turns off the power supply to a working product in emergency situations.

Few users know where the name of the product for drying hair, a hair dryer, came from - sometimes a dry, hot, strong and rather gusty wind comes from the mountains to the valleys, to which the locals gave the name hair dryer.

The device of any modern model necessarily contains two particularly sensitive elements:

Fenov is not as complicated as it seems: there are a minimum of basic components, therefore, if you have basic knowledge of electrical engineering, you can figure it out if there is such a need. A full description can be found in the operating instructions for the specific product.

Typical faults

Let's consider the reasons for the failure of the main parts, because the failure of any of them guarantees the failure of the entire product, since it will not be possible to use it further without repair. You can carry out simple diagnostics yourself if you know the most typical problems these household appliances.

If your home handyman easily understands electrical household appliances, then you will not need the services of professional craftsmen - all of the listed failures can be eliminated yourself.

Safe Operation

In order not to visit the service center frequently and save time and the family budget, you must strictly follow all operating requirements:

- Use only standard, factory-made extension cords.

- Inspect the cord before each use of the product and do not wrap it around the handle when storing.

- You can only use the supplied attachments that come with the kit.

- Do not use the product in a room with high humidity and do not expose it to water.

- Install a special one in the air intake fine mesh filter, preventing hair from being sucked into the device.

- If any malfunction occurs, immediately disconnect the product from the electrical network.

- Do not pull the cord from the outlet or carry the device by the cord. Remember that the wires inside are not steel, but copper, which can be damaged by mechanical stress.

- Don't overheat the hairdryer, if you need a device for long-term use, purchase a professional device designed for long-term operation.

- Before storing the device, you must give it time to cool for at least half an hour.

- The product must be stored in a dry place, the drawer must be locked.

If you follow all the recommendations exactly, your hair dryer will work without repair, and your hair will look flawless and stylish.

A hair dryer is an electrical device, which is a piece of pipe through which high speed a flow of air heated to 60°C is supplied in a given direction. Often, for ease of use, the pipe is equipped with a pistol grip.

The photo shows a Melissa Magic hair dryer with a power of 1600 W. There is an operating mode switch on the handle, with which you can turn on the hair dryer and stepwise change the temperature of the air emanating from its nozzle.

Construction hair dryer appearance, operating principle, structure and electrical circuit are practically no different from a hair dryer. Only in it the air flow heats up to 600°C.

The device and principle of operation of the hair dryer

When the hair dryer is turned on, cold air from the room is sucked into its pipe using a rotating impeller mounted on the shaft of a DC electric motor. Next, the air flow passes through a tetrahedral heat-resistant frame made of mica or ceramic, on which a heated nichrome spiral is wound. When cooling the spiral, the air flow heats up to a temperature of 60°C, and in construction up to 600°C, after which it exits the pipe.

There is usually a switch on the body of the hair dryer, combined with a stepwise setting of the operating mode, which allows you to turn the hair dryer into full or half power mode.

The photo shows the appearance of a typical slide mode switch.

To prevent skin burns when drying hair and destruction of the hair dryer body if the engine malfunctions, it is installed on the frame thermal protection in the form of a bimetallic plate.

When the air is heated above a set temperature, the bimetallic plate bends upward along the arrow in the drawing and opens the contacts. The heating coil is de-energized and air heating stops. After cooling, the bimetallic plate returns to its original position and the contacts close again.

As you can see, the operating principle and design of the hair dryer is not much different from other heating devices. household electrical appliances and any home craftsman can repair a hair dryer.

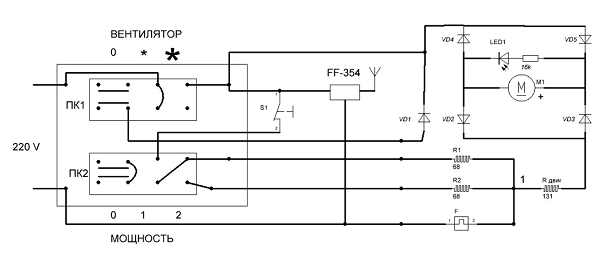

Electrical circuit of a hair dryer

Most construction hair dryers and hair dryers have the electrical diagram below. The supply voltage is supplied through a C6 type plug using a flexible cord. Capacitor C1 serves to suppress noise emitted by the motor brush assembly. Resistor R1 serves to discharge capacitor C1 after disconnecting the plug from the socket to prevent electric shock to a person when touching the pins of the plug. In some models, elements C1 and R1 are not installed.

The hair dryer operating modes are controlled using switch S1. In its position shown in the diagram, the hair dryer is off.

When the switch slide is moved one step to the right, its moving contact closes pins 1-2 and the supply voltage through the rectifier diode VD1 is supplied through the current-limiting coil H1 to the motor and heating coil H2. The diode cuts half of the sine wave and thus reduces the rotation speed of the impeller and the heating power of the H2 coil by half.

When you move the engine one more step, contacts 1-2-3 close, the heating element and the motor are supplied with all the mains voltage and the hair dryer operates at full power.

Typically, hair dryers are equipped with DC motors designed for a supply voltage of 9-12 V. The H1 coil is used to reduce the voltage. To convert alternating current to direct current, a diode bridge VD2-VD5 is used. Electrolytic capacitor C4 smoothes out ripples. Spark suppression capacitors C2-C3 perform the task of extinguishing sparks in the brush-commutator assembly of the engine and suppressing radio interference.

Button S2 is used to switch the hair dryer to cold air mode. When you press it, the H2 coil stops heating.

To protect the hair dryer from overheating, which can occur due to a decrease in impeller speed in the event of an engine malfunction, a thermal protection element St is used, which opens the supply voltage supply circuit to the H2 heater when the maximum permissible air flow temperature is exceeded.

How to repair a hair dryer yourself

Attention! Care should be taken when repairing an electric hair dryer. Touching exposed wires and live parts can cause serious damage to your health. Do not forget to remove the hair dryer plug from the outlet when making repairs!

If you receive a broken hair dryer for repair, then first of all you need to find out why external signs The hair dryer was found to be faulty. Based on them, using the table below, you can immediately guess where to look for the fault.

| External manifestations, causes and methods of troubleshooting hair dryer | ||

|---|---|---|

| External manifestation | Probable Cause | Remedy |

| When drying hair, the hair dryer turns off periodically | The power cord is frayed where it exits the hair dryer body or plug | Repair or replace the power cord or plug |

| The air coming out of the hair dryer is hot and has a burning smell. | Insufficient rotation speed of the impeller as a result of hair being wound onto the motor shaft between the impeller and its housing | |

| The hair dryer turns off after a short period of use | Thermal protection is triggered due to insufficient rotation speed or stopping of the impeller as a result of hair being wound onto the motor shaft between the impeller and its housing | Remove hair from the shaft with a sharp tool |

| Hairdryer won't turn on | The power cord is broken or the mode switch is faulty | Repair or replace the power cord or switch |

| Cold air comes out of the hairdryer | The heating shutdown button is faulty, the spiral is broken, the contacts in the thermal protection element are oxidized | Check parts with a multimeter, repair or replace faulty ones |

| The hair dryer only works in one of the mode switch positions | The mode switch is faulty, one of the spirals or diode VD1 is broken | Test the switch, diode and coil with a multimeter, repair or replace faulty parts |

How to disassemble a hair dryer

Disassembling a hair dryer can be more difficult than repairing it, since the body parts are usually connected inside using latches, the location of which outside can not see.

But there is always a self-tapping screw on the handle in the area where the power cord enters the housing, usually covered with a decorative plug or sealed with a label. Thanks to different colors parts of the body of the Braun hair dryer shown in the photo, you can see which line to disassemble it.

This is what the decorative plastic plug in the hair dryer body looks like. Since it is the same color as the handle, it is difficult to notice. To remove the plug, you need to pry it by the edge with a sharp object, for example an awl or a knife with a sharp blade end.

After removing the plug, the head of the screw became visible, but it turned out that the slot on it was triangular, and its edges were made in such a way that the screw could only be screwed clockwise. The manufacturer has provided that it is impossible to disassemble a hair dryer for repairs at home without breaking the case.

To unscrew a screw with such a head, it was first heated using the tip of a heated electric soldering iron. To do this, just press the soldering iron tip to the head and hold for a couple of minutes. The heating of the self-tapping screw softened the plastic around the thread. Next, while the plastic was still warm, using a flat-blade screwdriver with a width equal to the length of the edge of the slot triangle, the self-tapping screw was unscrewed without difficulty.

To avoid difficulties during the repair of the hair dryer during assembly, the self-tapping screw was replaced with the same size, but with a slot in the head for a Phillips bit.

The removable part of the body was additionally held on by four more latches. Two of them were located on the sides of the pipe. To disassemble, I had to simultaneously press the parts through the resulting gap using a flat screwdriver while moving the parts apart.

After disengaging the side latches, the top ones released themselves. The latches were shallow, so I was able to disassemble the hair dryer without breaking them.

In this hair dryer, the power cord was faulty, and therefore further disassembly was not necessary, since the place where the cord was connected to the electrical circuit became accessible.

Examples of hair dryer repair

Most often, hair dryers break down due to chafing of the power cord or malfunction of the electric motor with the impeller. In modern hair dryers, due to the presence of thermal protection and the use of thick wire for winding the spiral, it burns out very rarely. Out of the dozen hair dryers I have repaired, I have never encountered a burnt coil.

Hair dryer power cord repair

When drying your hair, the hair dryer moves intensively and the power cord constantly bends. Although the wires in the cord are copper and stranded, they break off over time due to repeated kinks. A sign of the beginning of a wire break is the periodic temporary stoppage of the hair dryer while drying your hair.

Therefore, half of the breakdowns are associated with fraying of the power cord at the point where it exits the housing, less often at the plug. The first sign of such a breakdown is interruptions in the operation of the hair dryer while drying your hair. At this stage it is easy to find out the location of the cord defect. It is enough to fix it in the middle and move the cord first at the entrance to the plug body, and then at the entrance to the hair dryer body. If the hair dryer works stably, it means that the cord is in order and the fault must be looked for elsewhere.

If the wires in the cord are frayed where they exit the plug, you can repair the hair dryer without disassembling it. How to replace the plug is described in the article “Electrical plug, how to connect, repair.”

Typically, the cord wires inside the hair dryer are soldered to a printed circuit board or connected using plug-in terminals, as in the photo above.

To check the cord, you need to ring the wires by touching one probe of a tester or multimeter to one of the pins of the plug. Using the second probe of the multimeter, touch the ends of the wires one by one. One of the wires should show zero resistance. There should also be zero resistance between the remaining wire and the second pin of the plug.

If the wires are ringing, then by moving the cord at this time you can accurately determine where the wire has frayed. In the product being repaired, the cord was broken where it entered the hair dryer.

If the wires of the cord are soldered to the printed circuit board, then you can ring them without unsoldering them by attaching the probes of the device to the pins of the plug. The hair dryer switch should be set to maximum power mode. The heating coil has a resistance of about 30 ohms. Therefore, if the cord wires are working properly, then the multimeter should show the same resistance.

By using online calculator You can accurately calculate the resistance value of a hair dryer's nichrome coil based on its maximum power.

In the hair dryer being repaired, the cord was broken at the point where it entered the body. To restore operation, you need to cut off the defective section of the wire and reinstall the plug-in terminals. To remove the terminals from the wires, you first need to use a knife to bend the antennae holding the wires to the sides, as shown in the photo.

In the next step, the frayed section of the wire is cut off and the insulation is removed from the cord and wires. The length of the cord will be reduced by ten centimeters, which will not affect the performance characteristics.

All that remains is to tin the wires and terminals using solder electric soldering iron and solder them together. After putting on the terminals, assembling and checking the operation of the hair dryer, the repair can be considered complete.

If you don’t have a soldering iron at hand, then the wires are cut off at a distance of 3-5 cm from the point of connection to the electrical circuit of the hair dryer and a section of the defective cord is removed. Then the wires are connected using one of the mechanical methods, depending on the internal free space in the hair dryer handle.

Engine power circuit repair

A Melissa-1600 hair dryer was repaired with a complaint that the air flow from it had become weak with a burning smell. Upon inspection, it turned out that the impeller was not rotating at sufficient speed. I immediately assumed that there was hair curled around the motor shaft between the impeller and the housing. Usually, in most cases with such signs, this is what happens.

But after disassembling the hair dryer, it turned out that one of the rectifier diodes installed on the motor was torn in half. Testing of the remaining diodes showed their serviceability. Therefore, the engine worked, but only one half-wave of rectified voltage was supplied to it.

The faulty diode was soldered out and in its place, observing the polarity, the first available type KD105 was soldered. The motor supply voltage is usually 9-12 V at a current of no more than 0.5 A. Almost any rectifier diode will provide such parameters.

At the same time, the curled hair was removed from the motor shaft and the bearings were lubricated with machine oil. To do this, just apply a drop of oil to the shaft fixation point in the motor housing and turn the shaft by the impeller several times.

Before installing the motor in the hair dryer, it is advisable to check it. For the motor to operate, a constant voltage of 9-12 V is required. But since the voltage is supplied to the diode bridge, the motor can be powered from either a direct or an alternating current source. Even the simplest adapter from any device will do, delivering the appropriate voltage and current up to 0.5 A.

Voltage must be applied to the input of the diode bridge, its soldering point to the electrical circuit of the hair dryer. If the engine is connected to a constant voltage source, then you need to check first with one connection polarity, and then swap the connected wires. This is necessary to check all the bridge diodes.

Tests of the engine after maintenance and repair showed that its impeller rotated easily when turned by hand and when voltage was supplied from an external voltage source at a sufficient speed.

Checking the hairdryer after assembly showed that its functionality was fully restored. The impeller rotated at high speed, and the burning smell disappeared.

Repair of the cold air switch and button

If the hairdryer cannot be turned on and the power cord is working, then the cause, as a rule, is a broken contact in the mode switch. And if all the modes of the hair dryer, but the air does not heat up, then the heating shut-off button, the heat protection is faulty, or the coil is burnt out.

Mode switches in a hair dryer are usually soldered into a small printed circuit board, which is fixed in the guides or screwed with self-tapping screws. The photo shows the switch leads soldered into the printed circuit board. On the left side you can see the hot air supply switch.

If the mode switch does not ring, then you can try to clean the internal contacts with a thin tool through the hole located next to its slider. It happens that only the contact of one of the operating modes has burned out, while the rest are in working order. In this case, you can sacrifice the rarely used mode of operation of the hair dryer and switch the switching to a working contact.

It happens that due to burnt contacts as a result of heating, the switch body is deformed and the motor jams. If there is no replacement switch, you can connect the wires directly, leaving only one operating mode for the hair dryer. In this case, you will have to turn on the hair dryer by connecting its plug to the outlet.

If the button to turn off the supply of warm air flow is faulty, and there is nothing to replace it with, then it is enough to short-circuit its leads. In this case, this function will no longer work, but otherwise the hair dryer will work as before.

Thermal protection repair

Thermal protection consists of two contacts in contact, one of which is fixed to a bimetallic plate. When the plate is heated above a given temperature, it bends upward, as shown by the arrow in the photograph. As a result, the contacts open and the power supply circuit of the heating coil is broken.

If the button to turn off the hot air supply is in order and the spiral is intact, then it is obvious that the contacts in the thermal protection relay have oxidized. To restore, it is enough to insert fine-grained sandpaper folded in half into the gap between the contacts and, pressing the bimetallic plate on top with your finger, pull the paper several times.

Malfunctions of the heating element - spirals

If the air flow from the hair dryer is cold when the engine is running, the shutdown button and thermal protection are working, then the breakdown is associated with the nichrome spiral.

A broken spiral can be easily detected by external inspection. And a violation of contact in connections in the form of hollow rivets on the frame of the hair dryer between the ends of the nichrome wire and the wires coming from the operating mode switch cannot always be determined by appearance. If the rivets are not blackened, then only testing with a multimeter will help.

To restore contact in the rivet joint, you need to further compress it using pliers. The work must be done carefully so as not to break the fragile mica or ceramic frame.

Burnout or breakage of the coil practically does not occur in modern hair dryers, but if such a failure occurs, the coil will need to be replaced with a new one. Splicing spiral wire by twisting or crimping it into a piece of aluminum or brass tubing will not lead to long-term success. If the spiral is worn out, then after such repairs it will soon burn out in another place.

A nichrome spiral, taking into account the power of the hair dryer, can be purchased new or wound independently from nichrome wire, calculating its diameter and length according to the table.

Removing hair and lubricating the hair dryer motor shaft

Another common malfunction of a hair dryer, which you can fix yourself, having only a standard set of tools on hand, is when the hair dryer is working, but the stream of outgoing air is very hot with a burning smell due to hair winding around the motor shaft or poor lubrication of the motor bearings.

Removing hair from the motor shaft of the BaByliss hair dryer

The BaByliss hair dryer shown in the photo came in for repair with the complaint that the outgoing air stream had become weak and very hot.

When checking, it became clear from the sound of the fan that its speed was too low, and the cause of the malfunction lay in the operation of the engine. To fix the problem, I had to disassemble the hair dryer.

In order to disassemble the BaByliss hair dryer, you first need to remove the nozzle by unscrewing two screws. Next, using a flat blade screwdriver, remove the fixing ring installed on the heated air outlet side. It gives in easily.

All that remains is to separate the body halves, which are held in place by two latches on each side. In the photograph, due to the translucency of the plastic, the latches are clearly visible, as in the photograph in the form of light stripes.

The hair dryer has been disassembled and all that remains is to get to the part of the shaft where the hair is wound. The engine is fixed inside a plastic housing, which is a pipe, in such a way that to remove it you need to remove the fan impeller. And the impeller, as a rule, is mounted tightly on the shaft, and here usually great difficulties arise, since it is impossible to grab the impeller with a standard tool, and it is easy to break it.

To solve such problems, I made a special tool from Chinese platypuses - a platypus with the ends of the jaws bent at right angles. With the help of a vice, the ends were easily bent, since they were not hardened.

I also successfully repair snake and zipper sliders with this platypus if the links stop closing. Regular pliers often cannot be reached. And thanks to the curved ends of the jaws, it is easy to squeeze the part of the runner that closes the links in any case.

In addition, the upgraded duckbill pliers are convenient for holding axles and shafts, nuts and other items different forms– do not slip out like with flat-nose pliers.

After removing the impeller from the motor shaft, access to the curled hair appeared. In this model of hair dryer, a brass bushing is mounted on the motor shaft, and an impeller is already put on it. Usually it is mounted directly on the motor shaft.

All that remains is to remove the hair with a sharp object, such as a knife, awl or needle, and collect the hair dryer in reverse order. To avoid any difficulties when assembling the hair dryer, I advise you to take several photographs when disassembling it.

Removing hair and lubricating the motor shaft of a Viconte hair dryer

The Viconte hair dryer external manifestation The malfunction was the same as that of BaByliss, but in addition the air came out with a burning smell and the fan worked with a grinding noise. This indicated that the engine bearings had run out of lubrication.

The sequence and technology for disassembling the hair dryer is similar to the BaByliss hair dryer, so there is no need to describe it.

The supply voltage was supplied via two wires to a diode bridge soldered to the motor terminals. For ease of repair, the wires were soldered using a soldering iron. The colors of the wires do not need to be remembered, since alternating voltage is supplied to the bridge, and the order in which the wires are connected does not matter.

An attempt to remove the impeller from the engine shaft using the platypuses described above was unsuccessful, even with the application of great muscle force. I had to figure out how to remove the hair and lubricate the bearing without removing the impeller.

The idea came to me that instead of having to worry about removing the impeller, I could drill a hole in the motor holder housing, which was done.

The location of drilling the hole must be measured so as not to hit the engine housing or the base of the impeller. First, a hole with a diameter of three millimeters was drilled, and then drilled out to five. The plastic of the case is soft and thin, so the hole can be made with the end of a pointed knife.

To remove hair from the motor shaft, a hook was made from a paper clip. To make such a tool, you need to bend the end of the paper clip, sharpen it on sandpaper and bend the very tip to a length of two millimeters. In a minute all the hairs were removed.

I had to use a medical syringe to lubricate the bearing. It is enough to apply one drop of oil to the shaft entry point into the engine. In order for the oil to get into the bearing, you need to hold the impeller and move the shaft along the axis several times, turning it.

The bearing on the opposite side of the shaft also needs to be lubricated. Any machine oil is suitable for lubrication, for example, for pouring into a car engine. If you don’t have oil on hand, you can remove the oil level dipstick from the engine and take a few dripping drops from it.

To check the operation of the fan, a voltage of 10 V was applied to the diode bridge from the DC power supply. The engine will operate at a voltage of 5 to 12 V, so even a charger from any phone will do. It is not necessary to do such a check, but if possible, it is better to make sure that the fan is working as expected.

The check showed normal engine operation, no extraneous noise and sufficient air flow. The hole you make does not need to be closed, as it fits tightly to the body of the hair dryer. If not, you can seal it with tape.

As you can see, the most common hair dryer breakdowns are not at all difficult to fix, and such work can be done by any home craftsman if desired. In any case, before buying a new hair dryer, you should try to repair a failed hair dryer.

When your fiancée's hair dryer stops working, it can turn into a tragedy...

Of course, you can please your beloved by purchasing a new one, but believe me, if you undertake to repair the old one and succeed, you will not only save your household budget, but also increase your status as an owner, husband and jack of all trades!

Of course, for many, repairing such devices will not cause any particular difficulties due to their own experience and knowledge, but not all are such fixers!)

Now, using a live example, we will look at some typical malfunctions of this type of equipment, and those who have never encountered such work will see that there is nothing overly complicated about it. Of course, there will be differences in different devices, but the principle is the same.

The first thing you should pay attention to is the power cord; often the wire breaks either at the base of the power plug or at the hair dryer handle itself. Moreover, a broken wire may visually appear to be in good condition because it is covered with rather thick insulation on top.

Such a malfunction is often detected by the fact that by bending the wire in the above places, the device can work. But make no mistake, operate with such a wire electrical devices This is not possible, the wire must be replaced.

To do this, you will have to disassemble the hair dryer, but this will also be needed to troubleshoot other problems. Let's get started.

How to disassemble a hair dryer

As a rule, all modern hair dryers, as well as other household devices of this kind, do not always have fastening bolts that are accessible and visible; they are often hidden behind various plugs or plastic panels which need to be unfastened. The patient for this article, an old Rowenta hair dryer, is no different in this sense.

Unclip and remove the plastic panel on the hair dryer handle

Using a thin flat screwdriver or better yet a short mounting knife, press the latches and remove the cover. Next you need to disassemble the mechanism for switching the speed mode. To do this, remove the switch wheel axis and remove the bar.

Then we remove another cover and only now can we unscrew the fastening bolts.

By the way, for this you often need a cunning screwdriver, such as a triangle, an asterisk, or a flat one with a slot; in my case, this is a homemade product made a long time ago from an old flat screwdriver, but now you can buy these.

Now that the two screws are unscrewed, for complete disassembly it is necessary to remove another plastic part of the case.

Well, we got to the insides.

Well, we got to the insides. Now, you can replace the wire and perform any other repairs.

What was the cause of the malfunction

In my case, the heater shutdown button was broken. Do you know what this button is for? Many, as it turned out, are not aware. The fact is that if you turn off the hair dryer immediately, without using this button, there is a risk of damaging the device. This can happen because the fan immediately stops after turning off, and the coil has not yet cooled down, the heat has nowhere to go, the hair dryer overheats, and you can even melt the body. And this button allows you to turn off and blow through the coil while the fan is running, giving it the opportunity to cool down somewhat.

So this very button failed, the fastening of one of the contacts broke, so the hair dryer only blew cold air. To repair it, I had to slightly widen the hole of the torn contact and, putting it in place, melt it with plastic to fix it. Of course, before this it would be correct to clean the burnt contacts.

In general, after these simple steps (it takes much longer to describe than to do), the hair dryer worked properly.

What other problems can you fix yourself?

Check the integrity of the power cord, plug, quality of connections, soldering. The button itself can also, if necessary, be disassembled for cleaning, but this must be done carefully so that the contacts and spring do not jump out (used in some buttons). If the button is seriously malfunctioning, it will already have to be replaced; this may not be possible due to the fact that it just can't be found.

The fan motor and the spiral itself are also difficult to repair - if they malfunction, either professional intervention is required, or...... Long live the store!

Another one possible malfunction repairable - thermal fuse.

This is a self-resetting fuse that turns off the heater coil when overheated, and after cooling it returns to its original, closed position. But it happens that its contacts burn out over time and it stops working normally. You need to restore good contact, carefully use something thin (a nail file works great while your wife can’t see) and shuffle between the contacts, but do not loosen them more than the thickness of the file. Otherwise, you will then have to bend the contact plates to compress them well.

Sometimes tucking is simply necessary. But be careful, it’s not that simple, remember that everything is attached to a fragile mica base and putting in effort can only make everything worse.

Remember that with any repair, care and accuracy are important! This is one of the keys to success!

Almost every home has a small device called a hair dryer. The hair dryer can be used when resining wooden skis, removing old paint, blowing sawdust from a workbench, dispersing mosquitoes and husbands, drying things, cooling a frying pan with dumplings and how to fan on hot days. A hair dryer is also suitable for drying hair.

Most hair dryers Chinese origin have a primitive electrical circuit. In such hair dryers there is only one switch, which turns on the fan and the thermal electric heater (TEH). Heating elements can be made in various modifications, but in all hair dryers they are made of nichrome twisted into a spring. More advanced hair dryers have two regulators: one regulates the blowing speed, and the second regulates the temperature of the blown air. At the same time, the scheme does not become smarter.

So, I came across a certain hair dryer made in China. The malfunction was the hair dryer's inability to change the blowing speed. There was no upper airflow limit.

As often happens in Chinese manufacturing, the self-tapping screws have a very strange head. A special screwdriver is needed for such a head. You can buy such screwdrivers, but bad luck, you couldn’t unscrew the Chinese screws with Chinese screwdrivers. Therefore, using a regular grinder from a screwdriver, you can make a cunning screwdriver under the head with the required screw.

Self-tapping screws can be used for a positive screwdriver, a flat screwdriver, an asterisk, a hexagon, a triangle, a square and a fork. In my case it was a fork.

On the handle there are control switches for regulating the functions of the hair dryer.

The hairdryer operates on 220 V, 50 Hz. There is a paper capacitor at the input to eliminate interference from the engine. The hair dryer has two regulators. One regulator includes a motor and a powerful heating element-4, and the second – auxiliary heating elements-1, heating element-2. Without turning on the blower, none of the heating elements will start working. When the blower is turned on at first speed, the voltage is initially supplied to diode VD1, designed for a current of at least 1 A. After the diode, the wires branch to heating element-3, which limits the voltage to the DC motor connected through the diode bridge VD2-VD5 and to the second blower temperature controller , switched on through a breaking temperature contact located inside the circuit with heating elements.

The voltage after the diode VD1 from 220 V becomes approximately 155 V, and the heating element-3 limits the voltage to the diode bridge to approximately 16 V. Capacitor C1 equalizes the pulsating voltage after the diode bridge VD2-VD5. At the second blowing speed, the VD1 diode is excluded from the circuit and the voltage of 220 V drops to the heating element-3, limiting to approximately 27 V.

At the first blowing speed with the heating elements turned on, the consumption is 0.9 A, but already at the second speed the current increases significantly to 6.8 A. The current corresponds to a load of about 1.5 kW. Principal electrical diagram hairdryer is shown below.

After unscrewing the two screws, you can remove the upper part of the hair dryer body. If you can’t remove it, plastic parts hold it in place. Sometimes additional screws are hidden with stickers.

The case contains switches, a set of heating elements wound on one frame and covered with a cover. The cover is needed to create an air channel in which air will circulate. If you remove the cover, then the heating element will heat up the air and melt the body of the hair dryer, so when making repairs, you should not heavily load the hair dryer without a cover. The cover is made of paper impregnated with a non-flammable base and painted with heat-reflecting paint.

This hairdryer has a gadget - an ionization button, but like everything in cheap equipment, this button only turns off the block of paired heating elements.

The diode bridge with a capacitor is assembled directly on the engine itself. This saved space.

In addition to Chinese cheap hair dryers for everyday use, there are professional-grade hair dryers. Typically, such hair dryers are made in Europe, but taking into account the fact that cheap work force concentrated in Asia, then there are professional hair dryers made in China.

The main feature of professional hair dryers is the presence of a non-16 V motor with voltage reduction through a heating element and power supply DC, and at full 220 V AC. By design, such a motor is classified as a single-phase AC commutator motor and is equipped with brushes. The use of such an engine allows you to fully use the ionization function, which allows you to completely turn off the engine heating elements.

A beautiful element is the frame with wound spirals. Typically, spirals are wound from nichrome (an alloy of nickel and chromium). Nichrome has a dark gray color. The resistivity of nichrome is on average 1.1 ohm*mm 2 /m. The length of nichrome wire L, m is calculated by the formula

L=U 2 *P*d 2 /4*P*p

Where U is the supply voltage, V;

P – number pi, P=3.14;

d – wire diameter, mm;

P – power supplied by the spiral, W;

p – resistivity of the wire, ohm*mm 2 /m, p=1.1.

If it is necessary to wind a coil for a hair dryer with a power of 1200 W, designed for a voltage of 220 V, the available nichrome wire has a diameter of 0.3 mm, then substituting the values into the formula we have

L=220 2 *3.14*0.3 2 /4*1200*1.1=2.6 m

To reduce the required length, the wire is twisted into a spiral, winding it around the rod.

Modern heating elements have a silvery metallic color and are not wound from nichrome. Nichrome soft material, and the metal in heating elements is hard and holds its shape perfectly. I don’t know exactly what metal is used in modern heating elements.

Malfunctions:

|

Malfunction |

Cause |

Elimination |

|

No increased blowing speed |

Replace diode bridge |

|

|

Capacitor C1 is faulty |

Replace (disconnect) capacitor |

|

|

No reduced airflow speed |

Diode VD1 is faulty |

Replace diode |

|

No heating of one of the heating elements |

The niphrom thread broke |

Find the break point and twist the two ends of the wire |

|

Hair dryer won't turn on |

No contact on switches |

Disassemble the switches, clean the contacts with alcohol and stretch the pressure springs |

|

The engine does not work |

Faulty heating element-3 |

Find the break point and twist both ends together |

|

Diode bridge VD2-VD5 is faulty |

Replace diode bridge |

|

|

Engine faulty |

Replace engine |