Tsugunov Anton Valerievich

Reading time: 4 minutes

When laying new linoleum, it is not necessary to contact specialists; you can handle this work yourself. The main difficulty lies in joining several strips in a large room, the size of which exceeds the width of the canvas, or at the border of rooms. If you do not pay due attention to the seams, dirt and moisture will get into them, the material will rise, and appearance the floor will deteriorate. But if you know how to glue linoleum together, this problem will be solved once and for all.

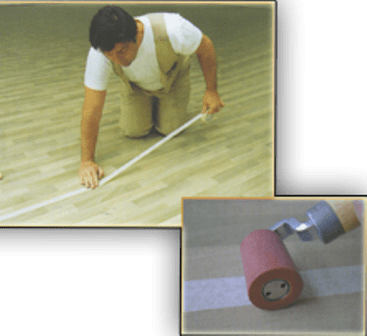

Using double-sided tape

Bonding linoleum joints with double-sided tape is quick, easy and cheap way, but with a short-lived effect. This option is suitable for lightly loaded or temporary connections. It will not be possible to reliably join a felt or fabric-based coating using this method.

A seam glued with tape will most likely not last long; the main danger for it is moisture that will get into the joint when washing the floor.

Procedure:

- The base is cleaned of dirt and dust and treated with strengthening primer.

- The parts of the coating are carefully joined.

- Tape is glued to the floor along the joint line. Then the top one is removed from it protective film and covered with linoleum.

- The edges of the material must be pressed tightly, and then the seam should be rolled with a hard roller.

Overhead connection

Joining linoleum at home can be done using overhead thresholds. They have an affordable price, they are easy to choose by color and composition (there are plastic and hardware). The thresholds have ready-made holes for self-tapping screws. The connection is reliable and durable.

The process consists of several stages:

- Using a jigsaw or a metal file, cut the strip to the required length and apply it to the joint of the linoleum. Holding the threshold, mark the exit points of the screws.

- A 6mm drill is inserted into the drill and holes are made according to the markings. Dowels must be inserted into them immediately.

- The threshold is applied to the surface and secured with self-tapping screws.

Bonding with mastic

Mastic is one of the most popular adhesives. It makes it easy to glue linoleum at home. The method is reliable, it connects “tightly”, but if you need to remove the coating for a while, then the linoleum will tear in the place where the mastic was used. It is also easy to attach the raised piece this way.

Work order:

- Before gluing the joints, prime the base.

- The edges of the coating are degreased with any alcohol-containing product. Acetone or solvents cannot be used, as they can corrode the linoleum.

- As soon as the base has dried, you need to apply a small amount of mastic to it with a spatula.

- Then the edges of the linoleum are applied to the surface and pressed tightly. The joint must be carefully rolled with a hard roller.

The mastic dries for about a day, so during this time the area where the coating has been treated should be pressed firmly with something heavy. A board is placed on the joined edges, and a load is placed on it.

You can glue linoleum joints using. This is very reliable way, which allows you to create a sealed seam that practically does not stand out against the background of the surface, but it is not suitable for all types flooring material. Hot welding can only be used for high-strength coatings; ordinary household linoleum will simply melt.

Hot welding is performed only on coverings that are firmly glued to the floor.

Gluing procedure:

- A special polymer cord (welding rod) is inserted into the hot air gun, which will fill the seam as the material melts.

- The edges of the linoleum are firmly joined, a small V-shaped groove is cut along the entire joint, a few millimeters smaller than the cross-section of the cord.

- The resulting gap must be cleared of debris and the edges of the linoleum must be degreased with an alcohol-containing solution.

- The hot air gun is heated to the temperature specified in the instructions (usually it ranges from 300 to 500 C°).

- The tip is placed at the beginning of the groove and slowly moves along it.

- The seam is completely filled with liquid polymer, which should protrude slightly above the edges. If the cord does not melt well, the temperature increases.

- After welding, the polymer is left in the seam until it hardens completely. Then the protruding excess is removed. While the cord is still liquid, this cannot be done, since the material shrinks. If you hurry, the seam will end up with a depression. Excess polymer is removed at the joints while the product is still warm.

Cold welding

- This is a method of gluing surfaces with special compounds. The technology eliminates processing with hot air. This is the optimal method for joining the edges of linoleum in an apartment. The compositions that are used for this (“A”, “C” and “T”) are selected in accordance with the type of material being joined and the size of the gap.

- If you need to glue a new coating immediately after installation, then type “A” glue is used. It has a liquid consistency, making it ideal for tight joints and goes well with soft coatings. It is inserted with a needle that comes with the tube. The seam is almost invisible.

- If the linoleum was laid a long time ago, then the edges are connected with type “C” glue. It has a thicker consistency than type “A” composition. The glue, filling the voids, reliably holds the seams together, preventing them from coming apart in the future.

- Type “T” glue is used to glue insulated PVC coverings on a felt or polyester base. It is toxic and difficult to use, used by professionals.

The gluing method using cold welding is very simple:

- The seam line is sealed with masking tape.

- Using a sharp knife, cut the tape exactly along the joint.

- Using a nozzle, glue is introduced into the gap between the edges of the coating.

- Excess welding is cut off after it has hardened.

Despite the fact that there is a huge variety of floor coverings on the market, linoleum is not losing its position. It is preferred by people of very different incomes and aesthetic tastes, and everyone finds the best option for themselves. To summarize, linoleum is a roll polymer material for finishing the floor. Its scope is extremely wide, and the range of types, characteristics and sizes available is also wide. In order for linoleum flooring to look just great, you need to correctly calculate its quantity and choose a material width that allows you to avoid joints or reduce their presence to a minimum. If this is not possible, then you shouldn’t be upset - there are methods that will help make the seams almost invisible. Let's try to figure out how to glue linoleum so that not even a trace of the joints remains. Is it possible? Maybe.

Today, several methods of inconspicuously connecting canvases to each other are known and widely used. To create a beautiful, tight and reliable seam, hot or cold welding of linoleum is most often used.

- on the type of linoleum (for example, for a commercial version of the coating, you can use both hot and cold welding), and for joining the edges household linoleum– only cold, since such a coating will not withstand high temperatures;

- on the complexity of the seam configuration (for example, when performing all kinds of applications with complex contours on linoleum, the seam will be made faster, easier and more accurately using cold welding).

Hot welding of linoleum seams

Using hot welding of linoleum joints allows you to get a very durable seam. It is carried out after the covering is already securely glued to the floor, using a special cord made of linoleum and a device for heating it:

- After the linoleum is laid with a minimum gap between the sheets, a chisel or other device is used to cut a groove (small groove) for the cord along the entire length of the joint.

- Thoroughly clean the joint area from dust and debris.

- The selected cord is threaded into a welding gun-hairdryer, which is then plugged into the mains.

- Under the influence warm air linoleum and cord soften, melt and firmly connect.

- Then the craftsman carefully cuts off the excess part of the cord protruding above the surface.

Despite the apparent simplicity of implementation, this procedure requires not only special devices, but also a certain skill that allows it to be performed efficiently. Cold welding is more suitable for doing it yourself.

Using hot welding of linoleum joints allows you to get a very durable seam

Cold welding of linoleum seams

Cold welding is a liquid and quick-drying special glue, which is sold in tubes with a needle tip, which serves for deeper penetration of the glue into the seam and allows you to reliably glue linoleum joints. Bonding occurs at the molecular level, which provides amazing strength to the joints of household, commercial, semi-commercial linoleum. This is especially relevant for foam-based coatings, since hot welding is contraindicated for it.

Its main advantages:

- it is quite possible to cope with the work without the involvement of craftsmen;

- ideal for use at home;

- can be used not only when laying flooring, but also for its repair.

There are two types of glue most often used: A and C. The difference between them is in consistency. Type C glue is much thicker and is used for gluing joints of old linoleum, which can be several millimeters wide. By filling the gap, it is possible to obtain a strong seam, which does not allow the canvases to diverge in the future, and holds them tightly together. For “freshly laid” linoleum, type A is suitable. This glue “works” a little differently: it actually melts, “welds” the edges of the linoleum.

Cold welding with type A glue should be carried out with gloves and an open window. Use a vacuum cleaner to thoroughly clean the seam from debris and dust. Masking tape is glued to the edges of the panels, which will protect that part of the linoleum that does not need to be melted. Carefully cut the tape over the joint of the panels. Apply glue by pressing the needle deep into the seam and lightly pressing on the tube so that the glue protrudes approximately 4 mm above the surface. After 15 minutes you can remove the tape. Cold welding with type C glue follows approximately the same pattern. True, you can do without tape, since the glue is thick and will not spread.

At cold welding masking tape is glued to the joints, which will protect that part of the linoleum that does not need to be melted

If during the renovation there is a need to join linoleum sheets, this is not a reason to be upset. For such purposes, cold and hot welding of linoleum is most often used. The latter option is more suitable for commercial coating; it requires special equipment and skills, so its use in everyday life is extremely rare, but cold welding is used more often, since the technology for its implementation is simple and accessible. When cold welding is performed correctly, you get an almost invisible, neat seam that does not spoil the appearance of the linoleum.

Linoleum is rightfully considered the most popular flooring. The impressive variety of colors and sizes, practicality and quite affordable cost of this material make it indispensable for finishing private apartments and public spaces. You don’t have to be a specialist to install the coating at home. It’s enough just to do the work carefully and know how to glue linoleum so that the joints are strong and invisible. The use of hot or cold welding will ensure a reliable and beautiful connection between the material sheets.

When is it necessary to glue linoleum?

Linoleum is a finishing material made from natural or polymer fibers. Laying such a floor covering will not be special labor, if only you know how to glue linoleum end-to-end at home.

The fact is that this finishing material comes on sale in the form of rolls 2 or 5 meters wide. There are no other options. If the room in which renovation is planned has a small area and you can cover the entire floor with a single piece, there will be no difficulties.

But much more often the rooms are no different correct form or the width of the room is more than 5 meters. In such cases, you have to cut out and lay several pieces of linoleum, which then need to be securely and discreetly fastened together. If this work is carried out poorly, water will penetrate into the joints, dirt will become clogged, and after a while the edges of the canvases will bend and twist.

It is necessary to glue linoleum in doorways and when replacing a damaged piece with new material. If the floor covering has a pronounced pattern or the designers decided to decorate the floors with colorful appliqué, it is also impossible to do without gluing the joints.

How can you connect linoleum at the joints?

To connect two or more pieces of linoleum into one, you can use the following methods.

- Pasting double-sided tape. This option is more suitable for creating a temporary coupling, and its main advantage is the speed of the work. The resulting seam will soon come apart and debris and dust will get into it.

- Installation of aluminum or plastic threshold. Good way to create a high-quality connection, however, it is appropriate to use it only in doorways.

- Hot welding.

- Bonding parts of linoleum by hot welding is used when laying industrial flooring in public spaces. This method requires professional equipment and skills, so it is not suitable for connecting household coatings at home. Cold welding.

To connect the canvases and create a sealed seam, a special glue called cold welding is used.

In everyday life, the latter method of gluing linoleum is mainly used.

Hot welding method Hot welding is most often used when laying industrial linoleum, which differs from household finishing material thickness, strength, wear resistance. Such flooring is laid in schools and hospitals, offices and, that is, where there is intense mechanical impact on the floors.

To get a high-quality and aesthetic seam, before gluing the linoleum together, you need to glue the PVC coating to the floor. Sealing of joints can begin no earlier than one day after gluing.

Hot welding is almost never used for gluing conventional linoleum. The fact is that the usual coating has a small thickness and does not withstand the temperatures that are used for joining by heating. In addition, to carry out hot welding, you must have professional equipment and certain skills.

To carry out joining by hot welding, the following materials and devices are required:

- special gun-hairdryer;

- cord made of linoleum;

- sharp knife or flat chisel.

To create a strong and reliable seam, you need to perform the following steps.

- Along the entire length of the joint (the sheets should be laid with a minimum gap and tightly glued to the base), a groove is cut with a chisel into which the cord will later be placed.

- The docking area is cleaned of dust using a vacuum cleaner.

- A linoleum cord is threaded into the holder of a welding gun, which is plugged into the network. The connecting cord can be purchased together with the floor covering.

- Under the influence of air heated to 400°C, the edges of the linoleum along with the cord melt and join. The result is a durable and almost invisible seam.

- The part of the cord that rises above the joint can be cut off with a sharp knife.

At first glance, the hot welding procedure seems very simple, but in reality it is not. When performing such work, professional skills are required; in addition, high-temperature welding poses a danger to the life and health of an inexperienced repairman.

Features of cold welding

To glue the coating at home, reactive adhesive compositions are used, which are otherwise called “cold welding”. They contain polyurethane and epoxy resin, have a very pungent odor and are highly flammable.

Reactive adhesive reacts chemically with the PVC material from which the flooring is made. The edges of the joints soften and dissolve into each other, resulting in a thin but strong seam that resembles real welding in appearance. This adhesive is especially important when laying foam-based coatings, since hot welding is not recommended for such materials.

Cold welding is sold in tubes equipped with a special needle attachment, with the help of which the adhesive reaches the most inaccessible places and allows you to firmly glue linoleum joints.

Cold welding has many advantages.

- Any novice craftsman can handle the work of laying flooring using cold welding, since the method does not require skills or abilities.

- Ideal not only for laying new linoleum, but also for repairing old coverings.

- No special equipment is required, which significantly reduces the cost of finishing work.

- The seam obtained using cold welding is distinguished by its solidity, accuracy and strength.

Gluing floor covering joints using cold welding does not require physical effort.

Types of glue

There are several types of adhesive used for cold welding. The choice of suitable adhesive depends on the composition and type of finishing material, as well as on the nature of the work being carried out.

- Type A

When laying new linoleum, type A cold welding adhesive is used. Due to the high solvent content, this adhesive has the thinnest consistency compared to other similar compositions, so it is advisable to use it to create seams no more than 2 mm wide. The main advantage of A-type glue is that the resulting seam is almost invisible and at the same time incredibly durable. The adhesive is best suited for hard linoleum with perfectly straight edges.

- Type C

This adhesive composition has a fairly dense consistency and is used for sealing seams 3–4 mm wide. Type C glue is used to glue the old coverings that have separated from each other. Type C cold welding not only glues the sheets together, but also fills the gap, as if creating an intermediate strip of linoleum.

- Type T

This type of adhesive is used extremely rarely by amateurs. However, professionals use it to join PVC and polyester fabrics.

How to seal linoleum using cold welding?

The technology of joining floor coverings using cold welding is not particularly difficult. The main thing is to carefully follow the instructions and carefully perform the work at each stage. Before gluing linoleum end-to-end at home, you need to prepare type A glue, tape, a knife, and gloves.

Do not allow drops of glue to fall on the surface of the coating.

In order not to stain the linoleum with glue and not to leave a blot that will be very difficult to remove, you must always use a soft cloth. When opening and closing the tube of glue, you need to hold it over this rag, protecting the floor from falling drops. If there is still a drop of glue left on the linoleum, it is better to wait until it is completely dry and remove the dry film with a knife.

Work on gluing joints should be carried out with gloves and with the windows open, as the glue has a pungent, unpleasant odor.

- Before sealing the joints, the first thing you should do is prepare them for joining - blot the moisture with a rag, use a vacuum cleaner to remove dust and debris accumulated in the cracks.

- The future joint is protected with masking tape. This is necessary in order to protect the edges of the canvases from glue.

- Using a sharp knife, cut the tape directly above the joint.

- Place a needle attachment on a tube of glue and squeeze the composition into the gap between the sheets. You need to squeeze out enough glue so that it protrudes 4 mm above the surface of the material.

- After 15-20 minutes, the tape is removed.

- You can use the finished floor covering an hour after completion of work.

A perfectly flat floor is extremely rare. There will always be small bumps and dips. If you make one long seam, it will bulge in uneven places. Therefore, experts advise gluing joints in small sections up to 70 cm long. new site should only be done after the previous one has dried. If you follow this technology, the seam will be smoother and more invisible.

When repairing linoleum, a thicker type C adhesive is used, so it is not necessary to apply tape. Otherwise, the process of joining the canvases completely repeats the activities described above.

Sealing linoleum at joints at home is not particularly difficult. The cold welding method will allow you to create a tight, durable and aesthetic seam, and this does not require special equipment or professional skills. The main thing is to choose the right glue and carry out the work carefully, without deviating from the instructions.

Bonding methods

Double sided tape

Threshold

Hot welding

Cold welding

The construction market is replete with a variety of floor coverings. However, regardless of such diversity, linoleum remains in demand as it has excellent properties and a low price.

It is possible to lay linoleum correctly provided that its width is selected correctly. It may not be possible to find the desired width, but this is not a problem because the pieces can be glued together. Let's look at how to glue linoleum together.

Bonding methods

You can choose a method after the coating has been laid. Eat various ways how to glue linoleum end-to-end:

- double sided tape;

- threshold;

- hot welding;

- cold welding.

Each method has advantages and disadvantages. Next we will talk about each method in more detail.

Double sided tape

Let's look at how to glue linoleum end-to-end. The execution technology is as follows:

- Under the junction, the floor is cleared of debris and dust; if necessary, the surface is primed.

- The joints must match perfectly; if necessary, the edges are trimmed with scissors or a sharp stationery knife.

- The adhesive tape is glued to the floor and, gradually removing the protective layer from the adhesive area, the linoleum sheets are connected.

Advantages of the method:

- easy to perform;

- The price of adhesive tape is low.

Disadvantages include:

- the connection is unreliable;

- the docking location will be visible.

Threshold

To make the transition to other rooms, use the threshold method. Docking is done like this:

- The edges of the sheets are aligned.

- The threshold of the required length is measured and cut using a metal saw or jigsaw.

- The threshold is fixed to the floor with self-tapping screws through the existing holes (more details: “Which thresholds for linoleum to choose according to shape and size”). If necessary, holes are drilled in the floor for plastic plugs.

Advantages of the method:

- the connection is reliable;

- the price of the material is low.

Disadvantages of the method:

- it is difficult to choose the same color of the threshold as that of linoleum;

- the threshold will stick out above the floor, not everyone will like it.

The problem often arises: how to glue the seam of felt-based linoleum? The use of glue here is not advisable, since only a layer of felt is glued, and the top layer is separated.

Therefore in this case the best option this is the use of a threshold. Almost any adhesive for gluing linoleum contains toxic substances. When working with them, you should definitely ventilate the room. You can work with thresholds without ventilation.

Hot welding

Hot welding is the most reliable method of gluing. However, it is quite labor-intensive and requires additional tool, such as:

- welding hair dryer;

- nozzle for welding gun;

- special welding cords;

- special knives.

Let's look at how to glue linoleum seams using this method:

- The edges of the linoleum adhere very well to the floor.

- Recesses are made along the entire length of the joint using a special tool.

- Next, all excess pieces are removed.

- The welding gun is turned on. It should reach operating temperature (approximately 400°C). Then the nozzle is put on it.

- The cord is inserted into the nozzle and the hair dryer moves along the joint.

- After the seam has cooled, it should be cut with a special knife without interruption along the entire length.

The advantages of such a connection:

- the composition of the seam is almost the same as that of linoleum;

- the connection is reliable.

The disadvantages include:

- joining linoleum in this way requires expensive tools;

- such equipment is complex, so special skills are required to work with it;

- This method is not suitable for gluing ordinary linoleum, because high temperatures will simply melt it.

Hot welding is not suitable for use at home - it is not profitable.

Not everyone has the desire to buy an expensive tool and learn how to work with it. But if you do this professionally, then this is the best option. Read also: “How to seal linoleum - proven methods with examples.”

Cold welding

Cold welding is another option than gluing linoleum at the joints. The method is quite simple and reliable.

The following tools will be required:

- masking tape;

- ruler;

- cold welding.

Linoleum is glued using the following technology:

- The edges of the sheets should fit each other perfectly; if desired, you can make the pattern match.

- The edges are aligned.

- Then the edges are covered with masking tape.

- A slot is made.

- It is then filled by cold welding.

- When the weld is completely dry, you can remove the masking tape.

You should work very carefully, since cold welding is almost impossible to remove from the coating without leaving marks. If it does get on the linoleum, you need to wait for it to dry completely and very carefully remove the weld with a knife. Read also: “How to make a joint between tiles and linoleum and what to use for this.”

The advantages of this method include:

- easy to use at home;

- you can do everything yourself without involving a specialist;

- Can be used to repair linoleum flooring.

Which welding to choose, cold or hot, depends on several factors:

- material type;

- following installation measures;

- required seam shape.

If you need to get a strong and durable connection, then it is better, of course, to choose welding, and it doesn’t matter which one (for more details: “Welding linoleum seams - the pros and cons of methods”). This will be much more reliable than gluing linoleum with tape.

The most reliable way to connect linoleum sheets is to use cold or hot welding. Only from a savings point of view or if this is the only possible variant(joining a felt-based covering) it may be justified to use adhesive tape or a threshold for joining linoleum.

The article looked at how to properly glue linoleum in various ways.

What glue should I use for gluing linoleum joints?

Linoleum is one of the cheapest (price square meter material significantly lower than the price of laminate, parquet or cork) and unpretentious flooring options. It is perfect for rooms with regular high load and humidity, such as the kitchen, corridor or hallway.

How to choose the right glue

When laying linoleum, it is important to ensure that it forms a single sheet and that the joints are invisible. To achieve this, you will need to buy suitable glue for linoleum joints. It is important not to confuse and not to buy glue intended for connecting linoleum to the base. These, in particular, include gummilk, bustylate, acrylate and dispersion adhesives.

So which adhesive should you choose to best ensure the uniformity of your flooring?

The glue we need is called “reaction”; it is intended for cold welding of linoleum. When applied to the surface of linoleum, such glue reacts with it, melting its structure. The joints form an intermediate rigid strip. At its core, this process is diffusion, because the edges of the canvases dissolve into each other.

Types of glue

Depending on the type and age of the linoleum being laid, Various types reaction glue:

Reaction adhesive type A. Designed for gluing joints on new Lenolium. It has a liquid consistency and is applied to freshly laid linoleum. A seam filled with glue turns out to be durable and transparent; it can only be detected by touch.

Reaction adhesive type C. Designed for joints with large gaps.

Adhesive for gluing linoleum butt joints

The consistency is thick, it is used to glue the separated joints of old linoleum. The distance between the sheets in old linoleum can reach 3-4 mm. This glue is not intended for gluing canvases together, but for creating wide band between them.

Reaction adhesive type T. It is used to glue PVC linoleum, the basis of which is polyester.

Syntex glue or glue from Tarkett is excellent for cold welding of seams. You can also find glue for linoleum joints on the market called Econ. It is suitable for gluing all types of linoleum. Its consumption is only 50 ml per 25 linear meters.

Cold welding of linoleum

The “cold welding” technology is quite simple and includes the following steps:

- cleaning the crack from moisture and dust;

- sticking single-sided tape along the entire length of the joint;

- carefully cutting the tape at the joint;

- squeezing glue from the tube into the crack;

- removing the tape 15 minutes after applying the glue.

Watch the video detailed instructions and procedure:

An hour after the described work, you can safely walk on linoleum.

What to glue linoleum to - choosing glue and working with it

Why do you need to fix linoleum to the floor?

Methods for fixing linoleum

How to prepare a concrete floor for linoleum

Glue selection

Tape mounting technology

Fixing linoleum with glue

The simplest floor covering is linoleum. You can lay it yourself, but sometimes beginners have a question: how to stick linoleum on a concrete floor and whether it is necessary to do it.

Experienced builders believe that using the dry method - without gluing the canvas to the base - it is possible to lay linoleum only in small rooms (kitchen, hallway). For all other options, it is better to secure the roll covering not only around the perimeter (with baseboards).

How to choose glue for linoleum joints

Over large areas during operation, the soft coating will move in waves, which will ruin the entire appearance and lead to cracking and damage to the canvas.

Variety of roll floor coverings and adhesive compositions so large that choosing adhesive for linoleum on a concrete floor will be difficult for an inexperienced person. After all, if previously there was only one glue for this purpose - PVA, now manufacturers produce a lot of adhesive compositions adapted to a certain type of linoleum and the quality of the base.

Why do you need to fix linoleum to the floor?

Linoleum is an unstable coating; it can be affected by changes in temperature or humidity. Deformations in the form of waves can occur when moving heavy furniture, in places of heavy loads, for example, under computer chair. Crests and waves not only spoil the aesthetics of the room, but lead to cracking and damage to the canvas. And this means a reduction in the service life of the coating, additional costs for the purchase and installation of a new coating.

Therefore, when choosing what to glue linoleum to concrete (another base), you need to take into account such circumstances as:

- Room area - than bigger room, the greater the risk of deformation of the soft coating.

- Location of high traffic and high load areas.

- Number of fragments (strips, pieces) of linoleum. When installing a floor with a complex configuration (presence of projections, niches, turns), it is impossible to do without joining several elements.

The correct choice of fastening method is important not only for the long-term operation of the coating, but also (in the future) for easy dismantling. Therefore, if used a budget option linoleum, with the intention of replacing it in the future with a more high-status analogue, this circumstance must be taken into account. From what glue to glue linoleum to concrete floor, depends on the ease of dismantling in the future. After all, few people like tearing off the coating piece by piece over 2–3 days.

Methods for fixing linoleum

The roll covering is attached to the floor in three ways:

- Dry method- used in rooms with a small area (no more than 20 m2) - provided that a single piece is used. Linoleum is secured with skirting boards around the perimeter of the walls and a threshold strip in the doorway.

Advice: when fixing the roll covering in this way, you need to remember that modern plastic skirting boards are not able to reliably press linoleum to the floor due to their flexibility. Therefore, with the dry method, it is better to give preference to classic wooden baseboards, which will reliably press the material along the entire perimeter (provided that the subfloor is well leveled).

- Gluing linoleum double-sided construction tape - justified if the joining line of the flooring fragments is straight and the room has little traffic. The method is attractive due to its ease and speed of installation. The disadvantage is the short service life of such fastening: over time, the sticky base of the adhesive tape dries out and loses its properties, and at the joints the edges begin to curl up.

- Fixation with glue (mastic)- the most labor-intensive and costly method. Partial fasteners (joints) and full fasteners (entire area of the canvas) are used.

Before gluing linoleum to a concrete floor, it is necessary to evaluate the surface of the screed for existing defects. Installation of the floor covering begins only after all irregularities have been eliminated and the surface has been prepared.

How to prepare a concrete floor for linoleum

First, the surface is cleaned of dust and debris, including peeling or crumbling fragments of the screed. Large depressions are filled cement-sand mortar, small cracks are sealed with putty. Irregularities and differences from 0.5 to 1 cm are eliminated with self-leveling mixtures.

Advice: in case of large surface defects, it is advisable to level a new one cement-sand screed or a dry screed followed by installation of an even covering made of plywood or OSB (read also: “How to glue linoleum to plywood and how to do it”).

It is important to follow the repair technology concrete surfaces under soft floor coverings: only compounds intended for such work are used.

Usually the manufacturer writes on the packaging the scope of application of the mixture. The use of putties and plaster that are not intended for flooring can lead to premature destruction of the base and swelling of the linoleum.

For example, it is strictly forbidden to fill cracks and potholes with gypsum-containing materials: gypsum putty for walls and ceilings, Rotband plaster - the gypsum in these mixtures gives a quick setting of the layer, but does not provide sufficient strength, and can crumble at the slightest exposure to moisture. It is clear that this will not affect the service life of the coating for the better.

Before gluing linoleum onto concrete, the floor should be thoroughly swept, or better yet, vacuumed. Even the slightest pellets of debris will affect the result - very soon damage to the decorative layer can be detected in such places.

They complete the preparation by priming the surface - thanks to this, the base will evenly absorb moisture and gluing the linoleum onto the concrete floor will be easy, without additional applications of glue in places of increased absorption (adsorption), or the adhesive composition dries too quickly.

For dry installation method roll material priming the floor is also necessary - the top layer will gain additional strength and will not crumble over time.

Glue selection

Gluing linoleum to a concrete floor over the entire area is chosen when the coating is intended to be used for a long time, without the intention of replacing it in the near future with a more expensive and status one.

The main criterion when purchasing is whether the glue matches the type of linoleum. Given the variety of options, preference is given to dispersed formulations - they do not have a strong odor and are the least toxic.

The most popular are:

- Acrylate adhesive mixtures- have proven themselves well in high-traffic areas.

- Bustilat- the reliability of the adhesive is time-tested, ideal for insulated linoleum with a felt base.

- Gumilax- consists of natural ingredients. Glue is quite expensive, so it is more often used for natural linoleum so that the main quality of such floors - environmental safety - does not suffer.

- Mastic(bitumen or dispersion) - suitable for coatings with a fabric base.

- Conductive glue- in rooms with a lot of electronics, linoleum with an antistatic coating is laid, so conductive adhesive is quite suitable for such a floor.

- Forbo 525;

- KIILTO - universal option;

- Acrylic Polynomial – 101;

- Homakoll 208;

- Henkel Thomsit UK 200 BKB UK 400.

If the variety of brands and names makes it difficult to choose, you can contact a consultant at a hardware store or consult with a practicing craftsman.

Despite the development of technologies and materials, linoleum has been and remains the most popular floor covering. Over the years, this material has proven itself to be an excellent floor covering for commercial premises and offices, as well as ordinary apartments or houses.

This material can be laid quickly and efficiently, covering a large area in a minimum amount of time. If the premises are produced renovation work, then the linoleum is also quickly removed. This coating It is easy to clean, withstands heavy wear and does not lose its beautiful appearance. Today you can buy imitating different textures. A wide range of colors is also available.

During the Soviet Union, this material was produced in fixed sizes with a width of 1.5 m. Today, the choice of measurements is greater - you can purchase a coating 3 or even 5 meters wide. Despite this, it is often necessary to glue two pieces of material together. Many people would like to learn butt welding at home. Let's look at several technologies.

Why, when and why is it necessary to glue linoleum joints?

This flooring is very hygienic and quite mobile in terms of replacement. It is often used to finish floors in kitchens and hallways - these are places where cleaning is required especially often. These rooms are also places with high levels of humidity and are characterized by sudden temperature changes. The interiors of apartments in old buildings and the layout of the rooms make it necessary to glue the joints of linoleum.

You simply cannot do without gluing when finishing floors in various offices and other similar facilities. In addition, domestic manufacturers still supply floor coverings with a width of 1.5 m to the construction market. For small corridors this is a normal size, but for large rooms this is not the best choice. Therefore, during the laying process, the strips must be glued to each other.

Technologies for gluing linoleum

There are two options. So, you can use cold welding, which is applied using special adhesives, or a hot version - here a special cord with a hairdryer solders the joints together. Additionally, there are also subspecies. For example, there is nothing easier than gluing linoleum to the floor

They also connect the joints. You can use rubber or metal thresholds, which are recommended for use on other materials.

Hot way

Using this technology, linoleum joints are glued in commercial premises. This requires special welding equipment. You also need a special cord. Instead of welding equipment, you can use a heat gun.

So, a cord is laid at the joints. The laying width should be 2-3 mm. Then, using a hair dryer, which was previously heated to 500 degrees, the wiring is simply soldered to the surface of the linoleum. It must be taken into account that one cord should be no longer than half the part being soldered. The second piece of cord is placed on the soldered one with a small margin of 2-3 cm.

High temperatures allow the cord material to be soldered into the linoleum with the highest quality and hermetically sealed quality. To remove it, experts prefer to use a special tool for gluing linoleum.

This option is highly practical and even more reliable, but is more suitable for harder flooring. Unfortunately, for apartments and houses, manufacturers offer more soft materials who cannot stand such high temperatures. And therefore you need to know other options for how to glue linoleum end-to-end at home.

Cold welding

This is a great way to do DIY joint gluing. Cold welding is often used in everyday life and is considered very popular for such tasks. Why is the process called cold welding? It is carried out by gluing the floor covering inexpensively without the need to “force” the material at high temperatures.

How to glue linoleum end-to-end using cold welding

Its edges should be cut as accurately and evenly as possible. Then they are placed on top of each other so that one joint covers the other by about 3 cm. It is important that they are clean and dry. Before gluing linoleum to the floor, you need to apply paper tape to the material - it will reliably protect the decorative surface from the aggressive effects of the glue. It also serves as a marker for the gluing zone. The tape is applied not only to the top, but also to the bottom.

Next, the lower and upper strips of the flooring material are cut off simultaneously. Any remaining cuttings should be removed. Then both are rolled together using a special roller at the junction so as to level them at the same level.

The glue is applied to the seam area and distributed in doses over the entire length. After spreading it, there should be only a thin strip on the surface of the linoleum. You need to make sure that the glue does not get on the surface of the coating. Unfortunately, it is impossible to withdraw it.

After performing these operations, the glue is allowed to dry for ten minutes. Then the tape can be removed. Here's how to glue linoleum end-to-end at home - there's nothing complicated about it. The advantage of this method is that the seams are invisible, and they themselves can even be figured.

Disadvantages of cold welding

Cold welding is a very effective glue, but it should not be used on linoleum that has a soft base or insulation. In this case, the glue will not help achieve the most accurate joining. The seams will be very noticeable, and their appearance will become unaesthetic.

Glue selection

In the process of using cold welding, everything depends on the materials that are glued together. There are several types for different situations:

- Glue “A” has a liquid form and is suitable for working with hard linoleum.

- Glue "C". It creates a special layer on the surface of the seam and is used for gluing joints up to 4 mm thick.

- Glue “T” can be used to glue polyester materials.

Required Tools

Let's look at what tools you might need. The selection is made based on the type of linoleum. To work using hot technology, you will need scissors and an edge cutter for an even cut. Next, to apply the material, you should prepare a spatula, brush or roller.

Rubber hammers are used for pressing. For hot gluing you need a hot air gun and a cord. If cold welding is performed, then you need glue, a fairly sharp knife, a lot of rags and tape (paper and double-sided tape will do).

During cold welding, the needle from the container with glue should be fed as deep as possible into the seam.

This is necessary to get the required amount of glue. A rag will help quickly remove drops of glue from the surface. It is more convenient to work with the tube with both hands at once. The glue consists of very aggressive substances, so you need to work with it very carefully. After finishing work, it is recommended to ventilate the room. Now you know how to glue linoleum end-to-end at home.

As you can see, the procedure is simple and accessible to everyone. As a result, the flooring will take on a beautiful aesthetic appearance. There is nothing better than well laid linoleum. Gluing the seams will give floor covering even more aesthetically pleasing.