Selecting a location

The choice of location for a bathhouse depends on sanitary and fire safety standards. Dimensions, depending on building design standards - 3-4 sq.m. total area per person being washed. It is advisable that the bathhouse be located away from the road, in a quiet place, separated from passers-by by trees, outbuildings or a fence. You can also build a bathhouse on a steep slope. Only in this case, the bathhouse will look like a dugout with pillars for the terrace. An entrance in the form of a veranda terrace is a desirable addition to any bathhouse, as it serves as a solarium, a cozy place for relaxing and reading, an area for children’s games protected from the rain, and a place for carpentry, plumbing and various repair work.

Material selection

Best material for the construction of a bathhouse - pine or spruce logs or beams 12-20 cm thick. Our company builds bathhouses from rounded logs and profiled timber. Rounded logs began to be used in the construction of wooden houses relatively recently. However, the advantages of this material made it popular in Russia. The even, rounded shape of the logs makes it possible to achieve their tight connection. Chopped wooden walls absorb steam well and retain steam. Construction log baths reduces the time required to erect a structure.

When constructing the foundation, stone or rubble is used. The types of foundation depend on the type of soil, as well as the level of groundwater.

Bath structure

Of course, the main place in the bathhouse is the steam room .

An indispensable condition in it is high temperature, uniform heating of the washable and the possibility of using a broom. The door should be opened into the dressing room, and not vice versa, to avoid wet clothes. In order to reduce steam and heat loss, the door is designed with a low frame and a high threshold. Along the wall there are wooden shelves in 1, 2, 3 tiers, the length of the shelves is 170-220 cm. Even if the bathhouse is the smallest, it must have all the qualities to steam and wash at any time, and heating a small bathhouse will require less time and firewood .

Of course, the main place in the bathhouse is the steam room .

An indispensable condition in it is high temperature, uniform heating of the washable and the possibility of using a broom. The door should be opened into the dressing room, and not vice versa, to avoid wet clothes. In order to reduce steam and heat loss, the door is designed with a low frame and a high threshold. Along the wall there are wooden shelves in 1, 2, 3 tiers, the length of the shelves is 170-220 cm. Even if the bathhouse is the smallest, it must have all the qualities to steam and wash at any time, and heating a small bathhouse will require less time and firewood .

The dimensions of the dressing room are taken based on the fact that there should be at least 1.3-1.5 m2 per person, and a width of at least 1 meter. The dressing room must be insulated, the windows must be wide with high window sills, at least 140 cm from the floor. It should have everything: from clothes hangers to firewood and coal. Behind the dressing room there is a washing room or a combined room for washing and steaming. Each steamer must have at least 1 m2 of space.

The location of the shelves and the stove in a Russian bath is a very important matter; the shelves must be positioned so that the steam that comes out of the mouth of the stove does not burn the recipient and other people in the steam room. In addition, the ceiling in a Russian bath can and should be made significantly higher than in a sauna, and the number and height of shelves depends on this.

Bath heating

To heat the bathhouse and heat the water, stoves of the most varied designs are used, mainly heater stoves. The principle of their operation is based on the use of granite stones as heat accumulators, which are heated by the hot gases escaping from the firebox of the furnace. This way the water and stones are heated at the same time. The stove-heater is designed for burning wood (preferably birch) in a long-term mode. In each room of the bathhouse during bathing, a strictly defined temperature must be maintained constantly and without much effort. In the steam room - 50-55 degrees Celsius, in the washing room - slightly above human body temperature, about 40 degrees, in the locker room - no lower than 21 degrees

To heat the bathhouse and heat the water, stoves of the most varied designs are used, mainly heater stoves. The principle of their operation is based on the use of granite stones as heat accumulators, which are heated by the hot gases escaping from the firebox of the furnace. This way the water and stones are heated at the same time. The stove-heater is designed for burning wood (preferably birch) in a long-term mode. In each room of the bathhouse during bathing, a strictly defined temperature must be maintained constantly and without much effort. In the steam room - 50-55 degrees Celsius, in the washing room - slightly above human body temperature, about 40 degrees, in the locker room - no lower than 21 degrees

Construction of a bathhouse

The construction of the bathhouse is preceded by preparation necessary materials, which are transported to construction site, then unloaded and stored. Before bringing in materials, you should prepare a place for them. Timber, like boards, as well as other lumber should be stored on pallets. It is necessary to cover the unloaded material with film in order to prevent exposure to negative weather conditions.

Laying the foundation

In the basic configuration, our specialists install baths and houses on the so-called support-column foundation, consisting of concrete blocks (20x20x40 cm). Thus, depending on the landscape, the bathhouse rises 20-30 cm above the ground. When constructing a foundation of this type, fine crushed stone and sand are used. The support is placed on a bed of sand and gravel. The thickness of the pillow is 20 cm or more. In addition, our company’s specialists install pile-screw foundations.

Upon completion of all excavation work and laying the foundation, we lay the roofing material in two layers, and then lay the first crown of timber measuring 100x150 mm. Then the floor joists and timber intended for partitions are cut into the crown. Logs made of boards measuring 150x40 mm are installed under the floors, timber logs are installed under the partitions.

Upon completion of all excavation work and laying the foundation, we lay the roofing material in two layers, and then lay the first crown of timber measuring 100x150 mm. Then the floor joists and timber intended for partitions are cut into the crown. Logs made of boards measuring 150x40 mm are installed under the floors, timber logs are installed under the partitions.

Construction of a log house

After completing the strapping, you can begin building the log house. External walls are erected from 140x90 mm timber. Their thickness is 90 mm. Standard height The log house is 17 crowns (2.35 m). Jute is laid between the beams. The standard fastening material for walls is 200 mm nails. Experts recess the nail by 2-3 cm, so that when shrinking the fastening element does not rest against the upper beam.

Assembling the rafters

The next stage of building a bathhouse is assembling the rafters. Pre-sawed blanks are knocked together on one template. This is followed by lining the gables with clapboard. Glassine should be placed under the lining, which performs a vapor barrier function. The sheathed gables and assembled rafters are mounted in place. The sheathing is nailed to them.

Interior decoration

After all roofing work is completed, the time comes interior decoration. Subfloors, glassine, Ursa or Isover insulation (50 mm) are installed. The insulation is covered with glassine paper, and then a finished floor is constructed from a tongue-and-groove floor board, whose thickness is 28-38 mm.

After all roofing work is completed, the time comes interior decoration. Subfloors, glassine, Ursa or Isover insulation (50 mm) are installed. The insulation is covered with glassine paper, and then a finished floor is constructed from a tongue-and-groove floor board, whose thickness is 28-38 mm.

Next, specialists nail the ceiling through glassine to the rafter beam. The top of the ceiling is insulated. After this, glassine is laid in the attic, then the floor is nailed there. A staircase made of boards or timber leading to the second floor is being installed.

The final stage of interior decoration is the insertion of doors and windows. As standard, frames measuring 100x120 cm are installed, with a window or two sashes, with double glazing. The size of the paneled doors is 210x80 cm. The lining is made of lining on the doors and windows. The plinth is nailed in the corners, at the joints of the lining, and along the floor.

What Russian doesn't like driving fast? What Russian doesn’t like to take a good steam bath... And indeed, if a Russian loves a bathhouse, then God himself ordered it to be hotter.

In the sauna, everything is subordinated to one idea - to get great steam that is good for health. At the same time, the temperature in the steam room can be very relatively high. Properly selected types of wood, organization of proper ventilation and air circulation in the steam room serve to relieve the shock that the body receives through touch. Shock is the body's reaction to high temperature, in which all organs begin to work in overload. In small quantities (individually for each) it is only useful: adrenaline is produced, the body’s protective reserve is activated, the immune system is strengthened, and intensive cleansing of the body occurs

Therefore, with proper construction, there are no trifles. Every little detail is one of the nuances that work towards the main idea of the sauna - maximum heating without harmful consequences.

Many people think that a strong steam room is only for very healthy people, but for those who, for example, diseased heart, she doesn't fit. You can steam at a low temperature in a “suffocating” steam room and strain your heart healthy person, so even he will feel uneasy. And vice versa, a little time in a hot Russian bath is not harmful, but beneficial, but you should still take into account the recommendations of doctors.

Entering a well-built bathhouse heated to a high temperature, a person experiences a very pleasant sensation when inhaling hot air. If the construction technology is violated, in such a bathhouse within five minutes (depending on the state of health) a person may experience unpleasant sensations - nausea, palpitations , heaviness in his heart - he will want to go out. After the steam room, he will rest for a long time and may feel exhausted for some time.

The location for the bathhouse on the site should be chosen in accordance with sanitary and fire safety standards, the dimensions should be in accordance with building codes at the rate of 3-4 sq.m. total area per person being washed. The best material for building a bathhouse is dry pine or spruce logs or beams 12-20 cm thick. Chopped wooden walls quickly and completely absorb steam, while maintaining a constant temperature and humidity in the steam room. Aromatic substances contained in pine and spruce wood, released when elevated temperature and humidity, have bactericidal properties. You can build baths from red brick, rubble or natural stone, but walls made of stone materials with a sharp temperature change become covered with drops of water - condensation, heat up for a long time and cool down quickly.

To retain heat in the bathhouse, a low ceiling and a high threshold are made. A door measuring 70x170 cm is made from boards 40-50 mm thick into a tongue or groove in such a way (especially in a steam room) that it fits freely, with a gap of 4-5 mm on the side, into the folds of the frame, but at the same time is tightly covered along the edge canvases. The threshold is made 20-25 cm high, the window is made with an opening approximately 1 m high, double frames with a glazing area measuring 50x60 cm. The ceiling height in the steam room and washing departments is taken in the range from 2 to 2.3 m for quick heating of the room with minimal heat consumption energy.

During the construction of a bathhouse Special attention should be given installation of floors and drainage. The floors in the dressing room (locker room) are made warm from two floorings, the so-called black and clean. The clean floor is painted or covered with linoleum. IN brick baths they cover it ceramic tiles. When installing floors in the washing and steam rooms, first of all, it is necessary to ensure normal drainage of used water and its discharge into the sewer system (local system or using a sump and absorption pit). It is arranged in the form of an inclined surface made of water-repellent material (concrete, clay, etc.) with a slope towards a pit (small container), equipped with a water seal and connected by a drain pipe to an absorption pit. The pit can be made of any suitable material, but so that it is airtight. At a level of 10-12 cm from the bottom, the outlet end of the drainage pipe is inserted, and a plate is installed obliquely to it, hermetically secured on all sides, except for the lower edge, which should be 50-60 mm from the bottom. This device forms a water seal that prevents the penetration of unpleasant odors from the sewer.

The wooden floor covering is made along joists installed on support pillars using waterproofing. Floor boards are fixed with a gap of 5-6 mm to ensure normal drainage in case of severe swelling. For the same purpose, longitudinal chamfers are removed from the boards, making the top surface sloping. Floors made of solid coating are made on the same principle as a drainage base, but the pit must be located in the room itself, so it is covered with a drainage grate. The sewerage system must be equipped with a ventilation riser, which, to simplify the design, can be mounted on a drain made of asbestos-cement or metal pipe with a diameter of at least 100 mm; its upper end is equipped with a cap or deflector.

Whoever came up with the idea of putting a wooden floor in the steam room is understandable. It is not clear why many still do not want to give this up. If you walk through wet parquet floor wearing boots or barefoot, the floor will become dirty. It's the same in the steam room. In slippers or barefoot, after a shower or not, the floor will still become dirty very soon. It is strictly prohibited to coat it with varnish! Nothing in the steam room should be varnished. No matter how good (according to the manufacturers instructions) it may be. In addition, wooden floors do not dry out. Downstairs is the steam room high humidity and low temperature. A wooden floor will be a constant source of dampness, mold and foreign odors. Therefore, it is better to make the floor tiled. It will not be cold, and you can leave your slippers downstairs.

Arrangement of shelves and stove in a Russian bath- this is a special article. It is important here that the steam escaping from the mouth of the oven does not burn the person serving and other people in the steam room. In addition, the ceiling in a Russian bath can and should be made significantly higher than in a sauna, and the number and height of shelves depends on this.

Arrangement of shelves and stove in a Russian bath- this is a special article. It is important here that the steam escaping from the mouth of the oven does not burn the person serving and other people in the steam room. In addition, the ceiling in a Russian bath can and should be made significantly higher than in a sauna, and the number and height of shelves depends on this.

There is no point in making backrests - horizontal boards that are sewn onto the wall above the upper bench at the level of the back of a sitting person. If your steam room is made of deciduous tree, the problem that the needles burn and get dirty simply does not exist. They say that the walls get dirty with your back, but the backrests also get dirty and the benches get dirty. All this sometimes has to be cleaned. Clean only with fine sandpaper without any detergents.

All wooden structures baths must be treated with an antiseptic to protect them from rotting.

To heat a bathhouse and heat water, you can use stoves of a wide variety of designs, mainly heater stoves. The principle of their operation is based on the use of granite stones as heat accumulators, which are heated by the hot gases escaping from the firebox of the furnace. This way the water and stones are heated at the same time. The stove-heater is designed for burning wood (preferably birch) in a long-term mode.

The most common material for the construction of a heater is refractory brick in clay mortar with the addition of fireclay powder. The walls of the furnace are laid in half a brick or in a full brick with good ligation of rows and a thin mortar seam. To lay a firebox, heaters use about 150 bricks, 20 kg of clay and 20 kg of fireclay sand. A firebox with a ash pit, separated by grates and a boiler with a lid installed above them, is connected by gas outlet channels to the heater chamber, which is filled with granite stones weighing from 1 to 4 kg at the rate of 60 kg of stones per 1 m3 of steam room space. To speed up heating, about 25% (by weight) of cast iron pigs are added to the stones, which heat up faster and accumulate heat well.

The chamber is equipped with doors measuring 220x270 mm, through which food is supplied with a ladle or hose. hot water to generate steam. The capacity of the boiler or tank should be designed for a consumption of 7-10 liters of water with a temperature of 60-70°C per person being washed.

The stove-heater must be positioned so that it simultaneously heats all the rooms of the bathhouse - the steam room, washing room and dressing room. The foundation of the furnace is laid with a depth of at least 50-60 cm from rubble concrete or red brick. Between the foundations of the furnace and the walls, leave a space of 60 mm and fill it with sand. The chimney pipe is laid out of brick with a 19x19 cm channel or an asbestos-cement pipe with a diameter of 150 mm is used for this purpose. Wooden elements of the roof frame cannot be located closer than 150 mm from the pipe.

A practical and fairly easy-to-manufacture heater can be made from two metal barrels: one is used as a firebox, equipped with a combustion door measuring 270x260 mm, a blower with an ash pan and grates, the other as a heater. To increase durability, the grate is made of cast iron or iron, for example from reinforcement with a diameter of 14-16 mm. A water tank is installed on top of the firebox so that there is a distance of at least 25 cm between the grates and the bottom to store a sufficient amount of firewood; the tank is equipped with a tap. The heater is installed on legs (stands) and connected to the firebox with a chimney pipe with a diameter of 22 cm. It must have a door measuring 220x160 mm for supplying water to steam and a chimney pipe with a diameter of 150 mm.

A practical and fairly easy-to-manufacture heater can be made from two metal barrels: one is used as a firebox, equipped with a combustion door measuring 270x260 mm, a blower with an ash pan and grates, the other as a heater. To increase durability, the grate is made of cast iron or iron, for example from reinforcement with a diameter of 14-16 mm. A water tank is installed on top of the firebox so that there is a distance of at least 25 cm between the grates and the bottom to store a sufficient amount of firewood; the tank is equipped with a tap. The heater is installed on legs (stands) and connected to the firebox with a chimney pipe with a diameter of 22 cm. It must have a door measuring 220x160 mm for supplying water to steam and a chimney pipe with a diameter of 150 mm.

When providing a hot bath and cold water from the centralized highway it is advisable to use electric heater. It works on the principle of air heating electric heaters type heating element granite stones measuring 4-6 cm, total weight 30 kg. The power of the electric heater is 2.8 kW, it has four heaters of the NSVZh brand - 1.2/1.0 with a power of 1 kW each, operating voltage 220 V. The electrical circuit for servicing the stove includes a temperature controller and circuit breaker short circuits.

The electric heater is installed on an asbestos-cement slab at a distance of at least 100 mm from the wall. Electrical wiring is made of a four-core cable in a metal protective tube. Protection and control equipment is installed in the dressing room. The furnace body must be grounded. To avoid accidental burns from contact with the body of the electric heater, which heats up to 90-100T, they are surrounded by a wooden barrier.

Many private craftsmen who decide to build a bathhouse on their country plot should first of all become familiar with the main options and types of such a design. It's important to decide a large number of preliminary questions, and also carefully study the construction instructions.

IN Everyday life Most often you have to deal with the concept of a Russian bath, but there are other types of similar construction. They differ not only in nationality, but also in the method of construction and the degree of humidity. Each of them is worth studying in more detail, which will help you understand what type baths will do most.

In order for a bathhouse to fully satisfy personal needs, it is worth relying on personal requirements, needs and desires. These factors should be taken into account when choosing the main type of bath.

So, on what features is the general classification of modern baths based? Everything is relatively simple here. There are special parameters by which professionals distribute bath buildings. This may include humidity level, temperature, design features and national affiliation. Each type of design has its own individual characteristics, advantages and disadvantages, so each of them is worth considering in more detail.

Variety of baths by humidity

Depending on the temperature and air humidity, professionals divide baths into three main types. Structures of this type can be damp, dry-air, or water-based. Each of the options presented to your attention is characterized by its individual qualities and properties:

- Dry air baths are different temperature conditions from 60 to 120 degrees, and total humidity does not exceed 25%;

- Raw baths provide the opportunity to use steam at temperatures from 50 to 700 degrees. The humidity level in them is 80-100%;

- Water baths are more popular in Japan, not in Russia.

Modern baths differ not only in temperature, but also in the features of construction and location.

Structural features of baths

According to certain design features There are three main types of baths. Choice in in this case is carried out on the basis of indicators of ease of use, efficiency, financial capabilities and the size of the area intended for construction. There are three main types of bath buildings:

If there are sufficient funds and space suburban area allows, it is worth considering the construction scheme of a separate bathhouse.

Material for construction

If a separate bathhouse is being built, wood is used for manufacturing. Popular  buildings made of timber, which in professional language are called log houses. This is the most prestigious option among those who like to take a steam bath. A bathhouse and even a house can be built from dry profiled timber.

buildings made of timber, which in professional language are called log houses. This is the most prestigious option among those who like to take a steam bath. A bathhouse and even a house can be built from dry profiled timber.

Baths can be frame. During the construction process, they are sheathed with tongue-and-groove boards, and insulation is carried out mineral wool . No less common are buildings made not only of wood, but also of the more versatile brick.

Finnish saunas and baths

To decide what kind of bathhouse to build, it is worth understanding which steam is most preferable - wet or dry. The Russian bath is characterized by wet steam. Overall humidity levels are approximately 70% and overall temperatures reach 90 degrees above zero. Only true admirers of hot steam can tolerate such indicators, since for the average person a mode of 60 degrees and a humidity of 50% are suitable.

To decide what kind of bathhouse to build, it is worth understanding which steam is most preferable - wet or dry. The Russian bath is characterized by wet steam. Overall humidity levels are approximately 70% and overall temperatures reach 90 degrees above zero. Only true admirers of hot steam can tolerate such indicators, since for the average person a mode of 60 degrees and a humidity of 50% are suitable.

Concerning Finnish sauna, then it differs from a Russian bath in the overall temperature provided by the stoves used. If a regular bathhouse uses wood-heated heaters that pump in steam, then a Finnish sauna uses stoves that run on electricity. An important advantage of this heating method is the rapid heating of the steam room, as well as subsequent control over the main modes of the heating produced. The sauna will be appreciated by all steam lovers without exception. The temperature in them can reach 100 degrees, and the humidity reaches 10%.

In a sauna you can significantly increase the humidity levels and also reduce the temperature. If you achieve such indicators, you can even use a bath broom and get great pleasure from the bath.

Once the type of building has been chosen, you can begin its construction. Below is information regarding this process, from preliminary work to finishing processes. The construction of a free-standing bathhouse is described in detail, since this is the most common option. Built-in options are relevant only if they are included in the project of a house under construction; later, building in a bathhouse will be much more difficult, almost impossible, since utilities will have to be changed.

Selecting a site for building a bathhouse

The choice of location for construction should be carried out first. There are a few important advice regarding the placement of the construction site, which should be adhered to:

- The entrance to the building is from the south. The reason is that in the cold season there are fewer snowdrifts on the south side, moreover, in the spring the snow melts here first;

- The building must be erected separately from nearby houses, and at a distance of at least five meters. Connection with other buildings is permitted based on the project developed by professionals;

- The site must be flat, no slopes;

- It is better to locate the bathhouse further from the water, this will help to avoid the appearance of unnecessary additional moisture, as well as the foundation from collapsing.

After the site has been selected, it is worth drawing out the design of the building. You should not act on your own in resolving this issue; it is advisable to purchase a ready-made option or turn to professional designers.

Construction of the foundation

Finally, a covering is installed that will be secured and protected by the ridge. Fastening is also carried out using iron. After this, the cornices and high-quality gable overhangs are hemmed.

Floor installation work

As soon as the roof is ready, it will be necessary to carry out insulation work with the base, that is, the floor is being installed.

At this stage, the drain pipe is installed. After this, the place where the washing room will be equipped is poured. The pouring process can be carried out using one sheet of spacer, as well as two sheets of reinforcing mesh. Initially, the reinforcement is laid, then it is poured, then another layer is laid and everything is poured again. The remaining parts of the bathhouse are simply covered with material such as expanded clay.

Insulation is placed on the laid expanded clay, directly below the floor level. In this case, it is worth leaving a gap of about 3 cm. Then the floor is nailed and after that you can begin various street works; you should start hammering in the gables.

Furnace work

Furnace installation- This is the next stage of work when arranging a bathhouse. If you plan to carry out such work with your own hands, you should give preference metal structures. For this purpose, you can use steel sheets or pipe. The oven is made from the first square size, made from round pipe.

The firebox of such a stove deserves special attention. It is preferable to have two cameras. One will be used directly to burn fuel, the other will burn what was not burned in the first. Thanks to this design, much less harmful combustion products will be emitted into the air, but more importantly, the overall efficiency of the design will be increased by about 20%.

It is necessary to understand that metal furnaces are a large hot surface that can burn very strongly.

To eliminate this disadvantage, it is worth covering the stove with a special fire-resistant brick. Many experts hang a steel screen, that is, a convector, on the front side of the stove. It is able to distribute heated air flows throughout the entire bath room, thereby making the heating process even more uniform and faster. As a result, a special circulation of air masses is established, which significantly increases the overall service life of the furnace.

Interior decoration of the bath

Modern steam lovers are paying more and more attention to the aesthetics of the bath, as well as comfort. Owners are paying more and more attention to the interior of the bathhouse. Considering the fact that modern baths consist of such premises as a washing room, a relaxation room, and a steam room, it is worth knowing what material to use for this or that part of the structure. Currently there is a huge number different materials intended for finishing.

Any bath is characterized by high humidity levels, as well as high temperature conditions. To maintain this temperature, you must ensure that general scheme heating of all areas was strictly clearly and precisely defined. The choice of base material must be carried out according to the following principles:

- Not a single element of the bath interior or the finishing used should release resins or phenols into the air at any temperature. It is this principle of environmental friendliness that is fundamental in the process of choosing a finishing material;

- The surface of the finishing bases used should not crack. When changing conditions, the material should not lose its appearance and shape;

- Important waterproofing qualities must be present at the height.

The choice of type of finishing wood deserves special attention. It is worth knowing that oak and walnut are able to accumulate and retain heat, as they have high heat capacity. This will cause the fact that after a certain time it becomes difficult to breathe in the bathhouse, and in the process of accidental touching you can get a burn. It is better to buy linden, aspen and larch. Finishing with pine is also not an option; when heated, the wood releases resin that can cause harm in the form of a burn.

The choice of type of finishing wood deserves special attention. It is worth knowing that oak and walnut are able to accumulate and retain heat, as they have high heat capacity. This will cause the fact that after a certain time it becomes difficult to breathe in the bathhouse, and in the process of accidental touching you can get a burn. It is better to buy linden, aspen and larch. Finishing with pine is also not an option; when heated, the wood releases resin that can cause harm in the form of a burn.

When choosing a finishing material, attention is paid to the degree of durability. The most durable material is larch, which is durable. Its only drawback is its high cost, which is why it is often not used to decorate the entire room. To save money, larch can be used to make benches, and aspen or high-quality linden can be used for floors and wall surfaces.

All rooms of the bathhouse should be decorated with materials that have high antiseptic properties. Similar quality can be achieved by processing wood using impregnations and other modern means.

The finishing of the steam room and walls in the bathhouse should not be carried out in the first year after construction, but after a year, at least, and preferably after two or three, the structure shrinks over the course of one year and this will cause a distortion in the finishing.

Finishing can be done with a standard board, but this is a very costly process in terms of time and money. Each one is clearly adjusted; you will also need to carefully adjust and hide the heads of screws and nails so that they do not rust. You can replace ordinary boards with clapboard. Elements of this material are equipped with special grooves designed for fixing the planks to the sheathing or to the wall. The fastening process is carried out by screwing self-tapping screws into special grooves. This a great opportunity hide everything. Lining is very popular as a decoration for a bath room. The lining is safe, easy to use, and even a beginner can install it.

You can also arrange a cellar under the barn, which you can make yourself.

The material consists of boards that are quite thin in thickness and have a certain attractive relief pattern. There is also a locking connection, which is located on the long side of the end and ventilation holes located on the back side of the surface.

For finishing it is worth purchasing high-quality lining. If it is overdried, after a relatively short time it may swell as it absorbs moisture. Purchasing raw material will cause wide cracks to appear.

The surface of the products for finishing should be very smooth and dry; it is not worth treating it with different compounds to achieve a similar effect. When heated, the substances contained in the composition are able to exert negative impact on the human body. The exception is compositions made based on natural ingredients. Such substances can give the tree an attractive decorative shade, as well as provide it with antiseptic properties.

Completion of the construction process and video

In the process of building a bathhouse, it is important to remember that everything should embody natural attractiveness and naturalness. The interior of the bathhouse must be conducive to good rest, and also ensure an optimal level of security.

Washing in a country bathhouse is a pleasure available to everyone. Its construction does not require large financial investments. In a minimal plan, such a structure is erected in a few days.

In this article we will look at the topic of how to build the simplest bathhouse in your country house quickly and inexpensively.

Let's start by studying ready-made options, we will discuss the designs of walls, floors, stoves and sewers that are popular among craftsmen.

Design Features

The main conditions for the comfort of any bath are:

- Walls, floor and ceiling well protected from heat loss.

- Reliable insulation of structures from water and steam.

- Compact, quick heating oven.

- Effective sewerage and ventilation.

Examples of country baths

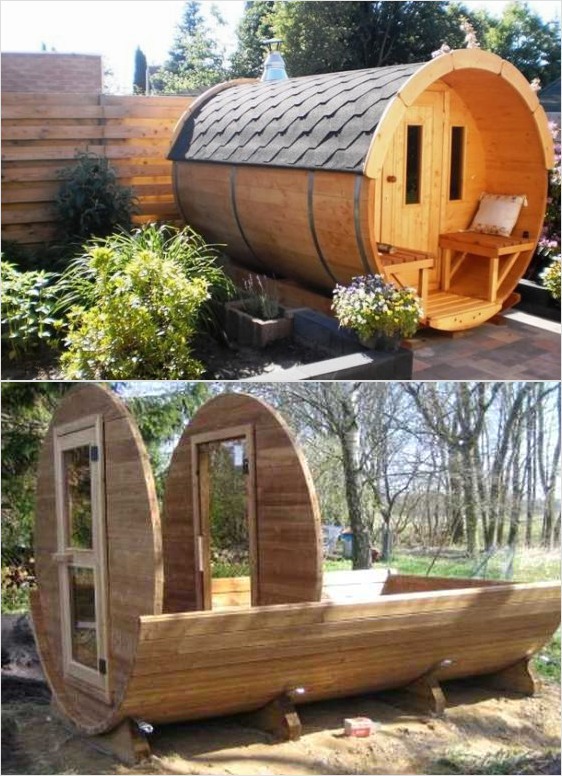

In photo No. 1 we see a simple bathhouse, reminiscent of Diogenes’ barrel. You can only take a steam bath in it. You won't be able to wash yourself here because there is no sewage system in the building. However, if desired, it is not difficult to do. To do this, you need to install a standard shower tray in the corner of the bathhouse and lead the drain pipe into the septic tank.

Photo No. 1 Build such a “barrel sauna” at your dacha and steam to your heart’s content

An important advantage of this design is its low weight, allowing it to be placed on a plank terrace.

The construction of the simplest bathhouse from the container category is shown in photo No. 2.

Photo No. 2 Container option country bathhouse

It consists of one steam room. For washing, the owner needs to attach a canopy with a summer shower or add a sewerage system to the room, and the stove - a tank for heating water.

Improvising on the theme of a barrel-shaped bath, let's turn our attention to cellular polycarbonate. You can quickly and easily assemble an original design from it. In order for it to retain heat well, it will take two large sheets this material and a frame made of metal or wooden bars. A mineral wool insulation 10 cm thick is laid between them.

The ends of the building can be made from boards, stuffed onto an insulated wooden frame. Place such a bathhouse anywhere: at your dacha, on a polar ice floe or on the top of Everest and you will always be comfortable in its steam room (photo No. 5).

Photo No. 5 Simple barrel-shaped bathhouse

A small Russian bathhouse, made from scraps of timber, can be installed on oak posts. Example similar structure we see in photo No. 6.

Photo No. 6 Oak posts are an excellent support for a small wooden bathhouse

Larger structures require their own foundation. There are three possible options here:

- Rubble concrete tape.

- Brick columns.

- Piles made of asbestos cement pipes.

Do not forget that the type of foundation affects the choice of material and wall design. Pile and columnar foundations are used for installation wooden frame, as well as for baths made of timber or logs (photos No. 7 and No. 8).

Photo No. 7 Bathhouse made of SIP panels on screw piles

Photo No. 8 Brick columns – best option for timber, log and frame structure

The “tape” of rubble concrete is suitable for any walls (made of gas silicate blocks, logs and frames).

A cheap, reliable and simple version of a bathhouse is obtained using technology. For such a structure you will need little: a truck of firewood, a cart of straw and a dump truck of clay (photo No. 10).

The best shape for a wood burning structure is round. It eliminates the need to reinforce masonry corners and looks aesthetically pleasing and original.

Borrowing from birds the technology of building nests from branches and clay, you can build such a simple and warm bath(photo no. 11).

Photo No. 11 Wicker frame coated with clay - “know-how” of an inexpensive bathhouse design

Recommendations for choosing finishing, insulation, sewerage installation, flooring, roofing and stove

For exterior finishing frame bath We can recommend the following materials:

- Wooden blockhouse.

- Metal tiles or corrugated sheets.

- Plastic siding.

- Cement particle board (CSB).

- OSB board.

- Flat slate.

Photo No. 12 A simple, but at the same time very nice option for exterior finishing of a bathhouse using unedged boards

It is best to use ecowool as insulation. It does not accumulate moisture, does not rot and does not burn. If ecowool is not available in your region, then you can buy ordinary mineral insulation in the form of a semi-rigid slab. It is easily and simply placed in the spaces between the frame posts.

To protect mineral wool from water vapor and reduce heat loss, the walls are lined with sheets of foil polyethylene. After this, a frame of slats is attached to them and trimmed with wood: alder, linden or pine clapboard (photo No. 13).

Photo No. 13 Steam and heat insulation of the walls of a country bathhouse built from any material

We do not recommend installing OSB board indoors. This material releases toxic gases when exposed to high temperatures.

Options for steam and thermal insulation of walls of a frame structure, as well as a bathhouse built from blocks or logs, are presented in Figure No. 1.

Building a simple bathhouse with your own hands includes sewerage. It can be made from standard plastic pipes, derived in cesspool or drainage well.

The water intake funnel is placed in the center or in the corner of the room, and the floor is made in the form of expanded clay concrete screed with a slope towards the drain. Before concreting, you need to compact the soil and cover it with several layers of waterproofing. Wooden floor - great option, but in the bathhouse it quickly rots and requires replacement. Instead, we recommend making gratings from wooden slats and laying them on a concrete screed. After washing, they can be removed, taken outside and dried.

The design of the bath ceiling is standard. First, a vapor barrier film is “attached” to the rafters and counter-battens (3x4 cm) are stuffed. A clapboard cladding is attached to them. The gaps between the rafters are filled with insulation and covered with under-roofing film. It protects it from weathering and atmospheric moisture (Fig. No. 2).

Fig No. 2 Ceiling structure of a country bathhouse

A counter-lattice is placed on the film, creating a ventilated gap between the roof and the insulation. The work on the installation of the ceiling and roof is completed by installing the main sheathing and laying roofing material(slate or metal tiles).

The main “detail” of any country bathhouse is the stove. It should provide rapid heating of the air and maintain a high temperature. A metal stove heats up the fastest.

To accumulate heat and create steam, it must be equipped with a compartment for stones. Options for stoves for simple baths A lot has been created, so we will not dwell on them in detail. Let's just say that the easiest way to make a heat generator is from steel pipe large diameter, old gas cylinder or barrel (photo No. 15). Another easy-to-use material is a steel sheet 3-5 mm thick (photo No. 16).

Photo No. 15-16 A simple stove made of a pipe and a stove made of ferrous metal

Mastering the simplest techniques welding work, you can assemble such a structure without outside help.

It won't be a big deal. You just need to bring in building materials and start construction. But in reality, it's not that simple. To begin the construction of any building, be it a house or a bathhouse, you need to comply with certain standards and rules, construction regulations. First you need to decide. To begin with, the most important rule is that the bathhouse should be located no closer than 15 meters from other buildings.

Also, if you adhere to all standards, you need to build a bathhouse near a reservoir, that is, there must be a reservoir on the site, or you just need to have a fire extinguisher, or maybe a barrel of water. Norms must also be followed. They must be of the second category, to which we include the Russian bathhouse. In this regard, the cable is inserted into the bathhouse through an asbestos-cement pipe. But the air entry is made using insulated wires into the corridor of the bathhouse or into the dressing room. According to bathhouse construction standards, installation of switches is not allowed in the steam room or washing department.

Standing sauna near a pond

Building materials

To build a bathhouse you need to use. But unless you take into account rocks that are not susceptible to rotting. One of these trees is birch. Experts recommend making baths from linden. This is such a healing tree that is suitable for building a bathhouse. Linden has no essential oils, fragrant - all this will add lightness to the steam, it will be truly healing. Linden also has a higher heat capacity and thermal conductivity, which means that the heating of the bathhouse will be much faster, and the temperature will remain much higher if built from some other wood. The biggest advantage of such a bathhouse is that it will never shrink, which means you can steam in it immediately after construction. The bathhouse construction technology also involves the construction of dry and seasoned wood. Its thickness should be at least 22 cm. If you build a bathhouse from freshly cut wood, then it can undergo enormous shrinkage and will take almost twice as long to heat up as a bathhouse built from dry material.

In or logs, natural tow is used without impregnation, just instead of enjoying the healing aroma in a beautiful Russian bath, you will have to, for a very long time and frankly speaking, uselessly try to get rid of any unpleasant odors of tow. Both in the construction of saunas and in the construction of baths, the most important construction norm will be the choice of board materials for. It’s better to build it from good quality thick boards, don’t skimp, you’ll regret it later. The gap between the boards should be from 6 to 8 mm. This is done so that all dirty water did not accumulate in one place. Most top shelf they make the stone backfill 5-7 centimeters higher, and at a distance of 110 cm from the ceiling. This is due to the fact that the distribution of steam occurs gradually, evenly from the lowest to the highest shelves.

Bathhouse construction standards state that nails in the bathhouse are strictly prohibited. Instead, wooden spikes or wooden dowels are used, the diameter of which will be from 10 to 12 mm. To protect the bathhouse from dampness and fungi, we need to consider what kind of ventilation we will have. Therefore, you definitely need to make an vent, the size of which will be 13 by 13 cm. Using this vent, excess steam will be removed. You can also use a heater stove as an outlet for ventilation. With the same goals they simply leave doors open furnace and blower. And there is also a window for steam to escape after finishing bath procedures. In winter, the washing room and steam room are ventilated with an open valve through an uncooled pipe in about 1-2 hours. And in the summer the bathhouse is ventilated almost without interruption. Heat must flow from the heater to all existing rooms, which means there is no reason to doorways in the partitions it is necessary to provide additional openings with closing doors of 400-600 sq. cm. In this case, the heat should be distributed evenly across the ceiling. Construction technology must include mandatory. This is done using foil or some other vapor barrier material that is odorless.

Traditional Russian log bathhouse

Bath floor

Traditionally, a Russian bathhouse should have a solid floor. Only on the ground, but if we make it only from wood, then it is best to do it on a layer of clay, this will help even more for better heat retention. In a steam room, according to the technology, drains are usually not installed under the floor. And if a drain is provided, then it is best to make a water seal so that there are no unpleasant odors. The place where they will be cleansed wastewater it is necessary to consult with sanitary services. If your bathhouse is built on the highest point of the site, then the outlet will be simply gorgeous.

Windows and doors in the steam room

It is best to place it on the west side, 60-80 centimeters below the ceiling in the bathhouse. This will allow us to use more daylight, and also reduce steam loss due to the fact that the glass has insufficient density. Also, do not forget about the norms of the doorway and threshold of the steam room. Simply the best height in doorway will be no more than 150 centimeters, and the threshold should be as high as possible, for example up to 30 centimeters. When the doors are opened, steam will not escape from the door opening, and cold will not flow through the threshold. Also remember that according to standards, the threshold must be made of hardwood. The thickness of the boards must be at least 60 centimeters. open only towards the exit.

Proper adherence to technology also provides for a good place to heat the heater. For example, if the dressing room into which the firebox door of the heater needs to be vented is small, then for additional air intake you need to open the door or window slightly, the combustion in the heater will simply be insufficient.

According to the norms and standards of bathhouse construction, the attic and gables need to be insulated this way: we insulate the voids under the rafters and insulate the voids between the roof and the planks.

Entrance doors to the steam room

Conclusion!

So, as we see, a bathhouse in a country house or on your own property is not a very simple matter. And like any other person, he will advise you to turn to great professionals. Since they are the ones who know all the nuances and subtleties in bathhouse construction technology. And building a bathhouse is a very responsible matter. For example, it determines what kind of pleasure we will receive after visiting the bathhouse, or maybe not. So decide to build it yourself or ask for help from professionals.